Product Categories

Contact Us

E-mail:

Aaron@bestconveyoring.com

Tel/WhatsApp:

+86 15230282222

Address:

Duikan Zhuang Rubber Industrial Park, Li County, Hebei Province

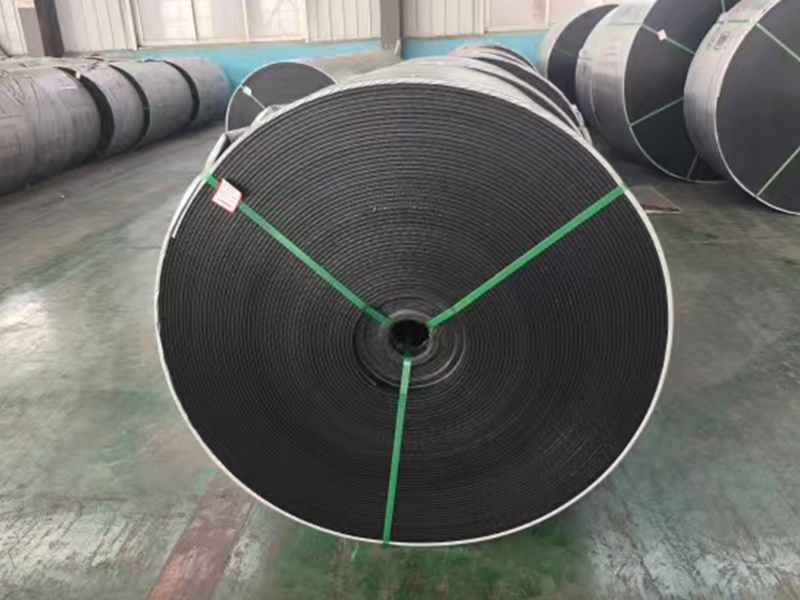

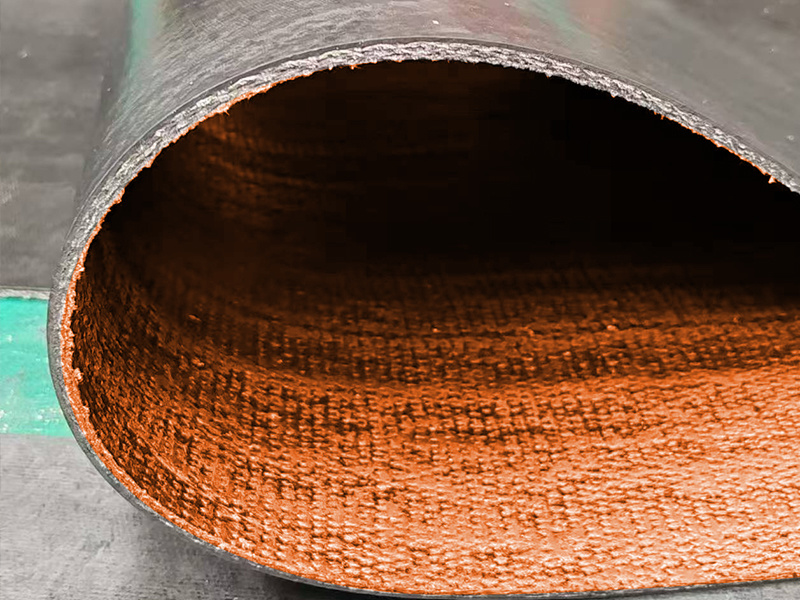

High wear-resistant conveyor belt

Heat-resistant (EP) polyester conveyor belt

Underground PVG solid-core flame-retardant conveyor belt

Flower patterned herringbone conveyor belt

Upper convex inverted V-shaped pattern conveyor belt

Backless/backless conveyor belt

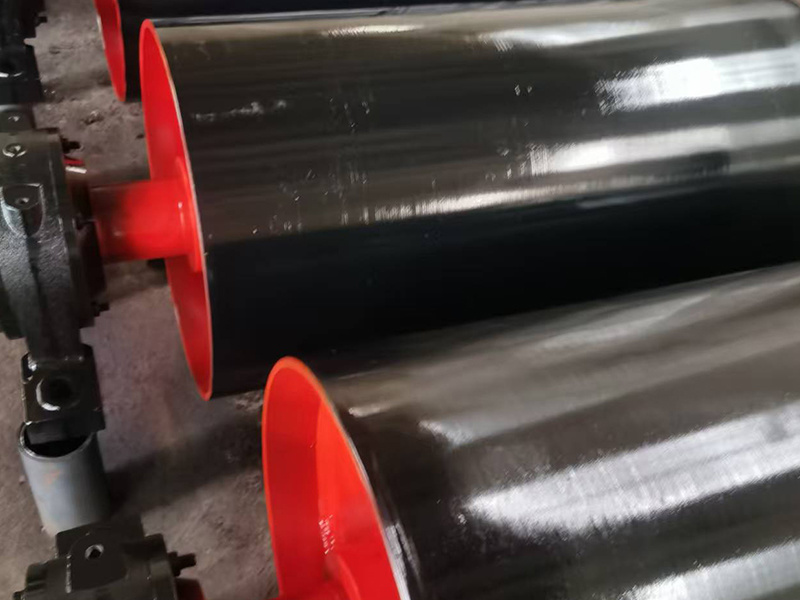

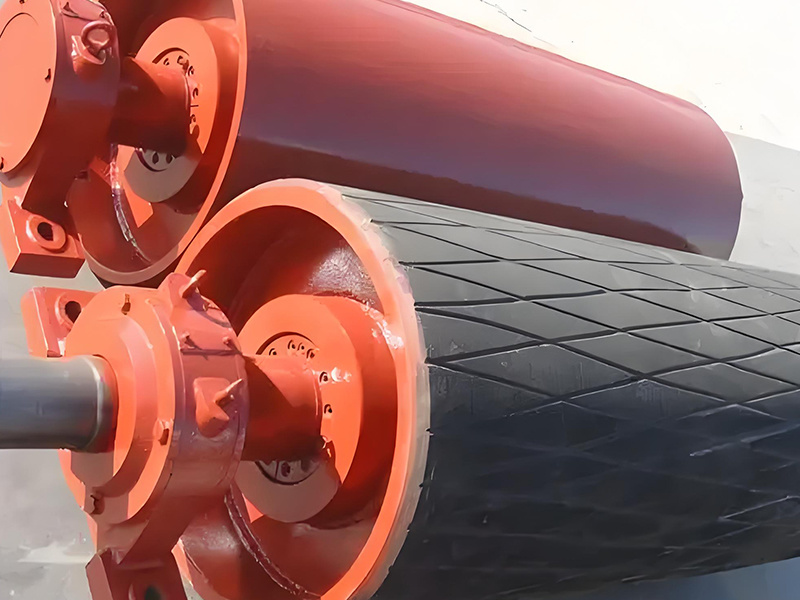

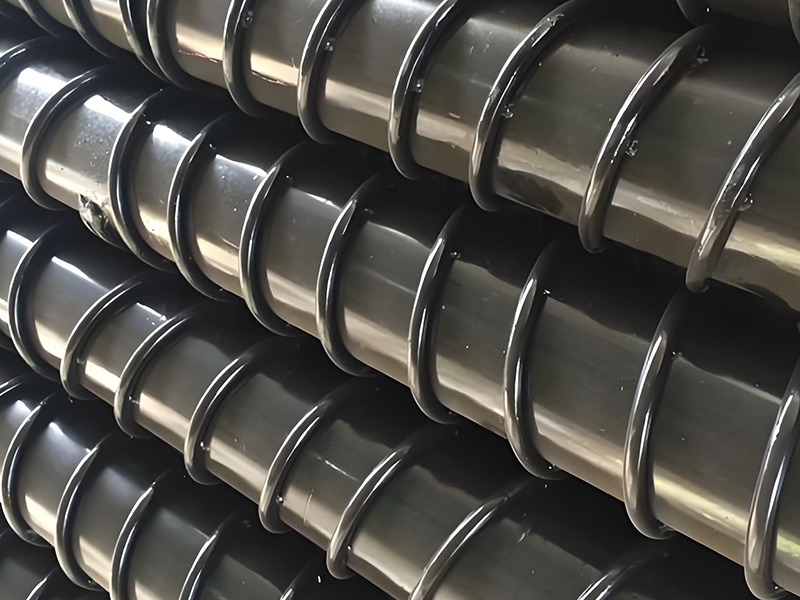

Idler roller group (self-aligning)

Rubber pad/rubber sheet/rubber block

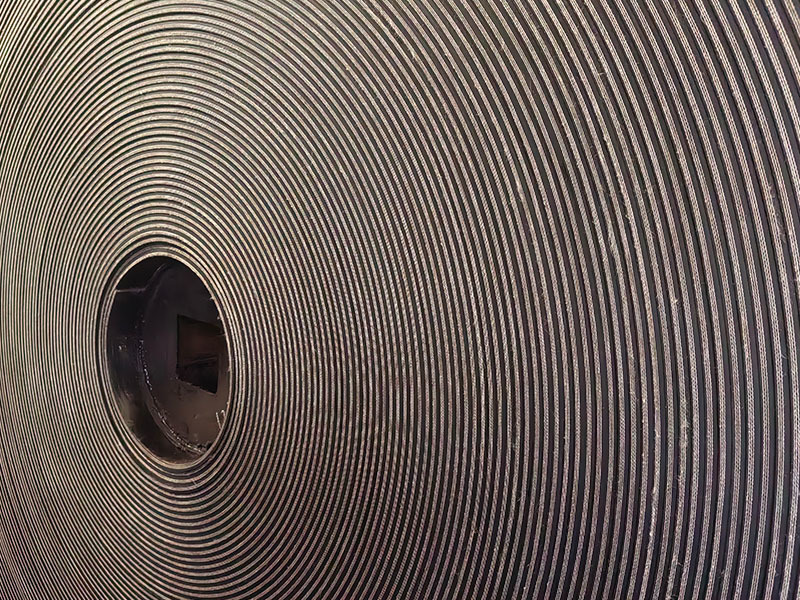

Corrugated sidewall conveyor belt

Oil-resistant NBR/MOR conveyor belt

Overall steel mesh/anti-tear mesh tear-resistant conveyor belt