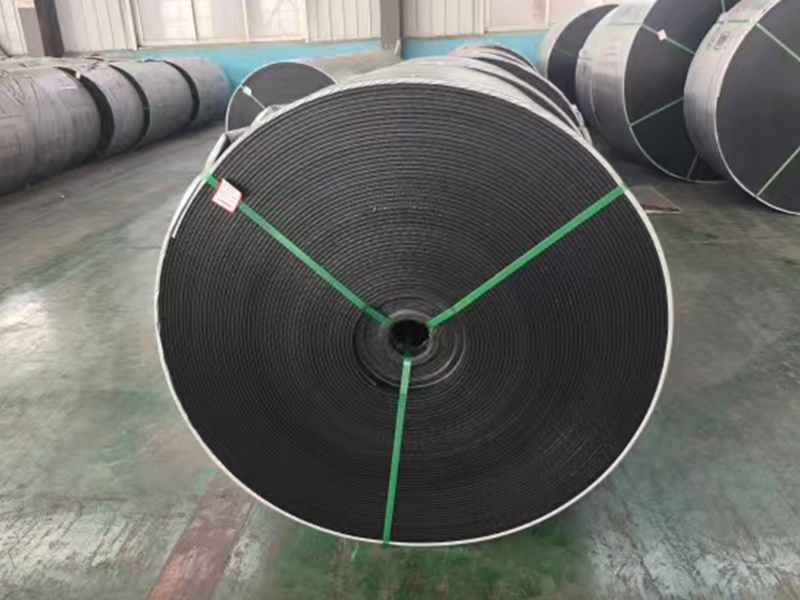

Extra-wide conveyor belt

Let our industry experts tailor a solution for you,Contact us!

Category

- Product Description

-

Purpose

Extra-wide conveyor belts are mainly used for high-volume material transportation in industrial sectors such as mining, steel, and cement; parcel and goods sorting and transportation in logistics; bulk cargo loading and unloading in ports; material transportation in construction; and grain transportation and processing in agriculture, etc.

Definition and Characteristics

Definition: An extra-wide conveyor belt refers to a conveyor belt wider than the conventional standard; its width can range from BW400mm to BW6500mm.

Extra-wide design: It can meet the needs of large-scale equipment and projects, improving material transportation efficiency.

High-strength materials: Usually made of high-strength canvas, steel wire ropes, or synthetic materials, it has strong tensile strength and wear resistance, capable of withstanding high loads and transporting large-sized materials.

Good tensile resistance: The special structural design and the use of high-strength materials ensure that the extra-wide conveyor belt has good tensile resistance during long-distance transportation, reducing elongation and deformation, and improving transportation accuracy and stability.

Strong adaptability: Suitable for various working conditions and environments, such as high temperature, low temperature, high humidity, and strong corrosion, meeting material transportation needs under special conditions.

Low maintenance cost: The special structural design and excellent materials used result in a longer service life and lower failure rate for the extra-wide conveyor belt, reducing equipment maintenance costs and downtime.

Energy saving: Usually using a lower transportation speed and larger-diameter rollers can reduce friction loss and energy consumption of the conveyor belt.

Application Fields

Extra-wide conveyor belts are widely used in multiple industrial fields, including but not limited to:

• Mining: Used for raw material transportation in large mines, such as coal, ore, and iron ore.

• Ports and Logistics: Used for cargo loading and unloading in ports, such as containers and bulk cargo, as well as rapid cargo transportation in large logistics centers.

• Building Materials: Suitable for the building materials industry, such as transportation of cement, sand, gravel, and gypsum boards.

• Steel and Metallurgy: Used for the transportation of iron ore and other raw materials, as well as the transfer of finished steel products.

• Grain Processing: Used for grain transportation and stacking, such as wheat, rice, and corn.

• Power: Used for coal and petroleum coke transportation in power plants and power transmission and distribution systems.

• Chemical Industry: Used for the transportation of chemical raw materials and finished products, meeting the requirements of chemical processes for special materials.

• Environmental Protection: Used for waste transportation and processing in waste treatment plants and waste recycling industries.

Cover Rubber Quality/Grade Standard Performance Parameters

German Standard DIN-22102 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Wear ≥mm 3 Bond Strength between Plies (N/mm) Bond Strength between Cover and Ply (/mm) Cover Thickness 0.8~1.5mm Cover Thickness >1.5mm W 18 400 90 ≥5 3.5 4.5 X 25 450 120 Y 20 400 150 Z 15 350 250 British Standard BS 490 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Wear ≥mm 3 Bond Strength between Plies (N/mm) Bond Strength between Cover and Ply (/mm) Cover Thickness 0.8~1.5mm Cover Thickness >1.5mm M 24 450 - ≥5.25 3.15 4.5 N 17 400 - Australian Standard AS 1332-2000 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Wear ≥mm 3 Bond Strength between Plies (N/mm) Bond Strength between Cover and Ply (/mm) Cover Thickness 0.8~1.5mm Cover Thickness >1.5mm A 17 400 70 6 4 4.8 E 14 300 - F 14 300 - M 24 450 125 N 17 400 200 S 14 300 250 S* 12 300 250 South African SANS 1173:2005 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Wear ≥mm 3 Bond Strength between Plies (N/mm) Bond Strength between Cover and Ply (N/mm) A 18 400 90 ≥7 ≥5 X 25 450 120 M 24 450 150 N 20 400 250 Specifications and Technical Parameters of Multi-Ply Fabric Core Conveyor Belts

Fabric Type Fabric Structure Fabric Model Rubber Belt Thickness (mm/p) Strength Series (N/mm) Cover Rubber Thickness Width Range (mm) Warp Weft 2 Layers 3 Layers 4 Layers 5 Layers 6 Layers Top Cover Bottom Cover Nylon

EP Polyester

NN

EE

Polyamide Polyamide Nylon/EP Polyester/NN/EE-100 1.00 200 300 400 500 600 0-12 0-10 300-2500 Nylon/EP Polyester/NN/EE-125 1.05 250 375 500 625 750 Nylon/EP Polyester/NN/EE-150 1.10 300 450 600 750 900 Nylon/EP Polyester/NN/EE-200 1.20 400 600 800 1000 1200 Nylon/EP Polyester/NN/EE-250 1.40 500 750 1000 1250 1500 Nylon/EP Polyester/NN/EE-300 1.60 600 900 1200 1500 1800 Adhesive strength and elongation performance meet the following table

Core material Adhesive strength Elongation performance Inter-layer N/mm Cover layer and inter-layer N/mm Total thickness longitudinal breaking elongation Total thickness longitudinal reference force elongation Cover layer thickness ≤1.5mm Cover layer thickness ≥1.5mm Polyester canvas ≥5 ≥4.5 ≥5 ≥10% ≤4%6 The covering performance of the tape meets the following table

Cover layer level Tensile strength Elongation at break Abrasion Change rate of tensile strength and elongation at break after aging Mpa Kgf/cm2 % mm 3 % H ≥24 ≥240 ≥450 ≤120 -25~ +25 D ≥18 180 ≥400 ≤100 -25~ +25 L ≥15 150 ≥350 ≤200 -25~ +25 Packaging details

1. Waterproof nylon packaging, with bottom steel pallet or wooden pallet.

2. Standard and appropriate export packaging.

3. Customized packaging can be provided according to customer requirements.

Shipping scenarios

Frequently Asked Questions

1. Can I customize conveyor belts to meet my business needs?

►Yes, we are specialized custom conveyor belt manufacturer , Focus on customized conveyor belt solutions. We work closely with our customers to customize the belt width, thickness, material composition, and various quality products according to the customer's specific operational requirements. This ensures that our conveyor belts perform ideally in different industrial environments.

2. What payment methods do you accept?

►We offer flexible payment methods to meet customer needs. Common payment methods include Telegraphic Transfer (T/T) and Letter of Credit (L/C) ,especially suitable for large orders. We can also negotiate other payment methods according to the agreement between both parties.

3. What after-sales service do you provide? How do you guarantee your quality?

►We provide comprehensive after-sales service support, including 24/7 technical support, installation assistance, and maintenance advice 。We also provide regular follow-up services to ensure smooth product operation and long-term satisfaction! We have an internal testing laboratory and adhere to the principle of qualified products before shipment! For many years, we have been one of the suppliers to internationally renowned companies, and our customers are located in various countries and industries, including mining, stone crushing, sand washing, ports, power, metallurgy, chemical, coal, steel plants, cement plants, and construction, and our excellent quality is widely praised.

4. How do I place an order? What is the delivery time?

►You can contact us via WeChat, WhatsApp, phone, email, and website to place an order. Regular models 5-7 days delivery ,the delivery time for other customized products depends on the product type and customization requirements.

5. Can I get a sample for inspection and testing?

►Yes, samples can be sent for testing before bulk orders. Samples are created according to customer requirements, allowing customers to evaluate the performance of the belts and rollers.

6. Can I print my LOGO on the conveyor belt products?

►Yes, we are a customized manufacturer, supporting processing, OEM, please inform us of your logo or design before mass production.

Why choose us?

1. Engineering design and consulting

Our conveyor belts are ideal for handling various heavy and abrasive materials for bulk material handling, successfully meeting the needs of various industries, including stone crushing and screening, sand washing, fertilizer, grain conveying, steel plants, power plants, cement plants, metallurgy, coal, ports, construction, etc. As a one-stop conveyor engineering manufacturer, we also provide excellent solutions for conveying materials and after-sales service for various applications.

2. Excellent customer service

We specialize in producing heavy-duty (nylon, EP polyester, EE, NN) multi-layer fabric core rubber conveyor belts, herringbone conveyor belts, circular conveyor belts, steel wire rope core conveyor belts, corrugated edge conveyor belts, bucket elevator conveyor belts, etc. As a high-quality conveyor belt manufacturer, supplier, and exporter in China, we focus on providing customers with high-quality conveyor belts and professional services.

3. Customization

Support OEM, meet all your needs, regardless of size, even if you only have an idea, we will help you realize it.

We have a strong R&D team that can develop and produce products according to drawings or samples provided by customers.

4. Cost-effective

Lower price for the same quality, better quality for the same price. Fast production cycle, short lead time, high efficiency, durability, and reliable quality. We are committed to the mid-to-high-end market, and our products meet international standards.

Our Advantages

Excellent production equipment

The company has introduced multiple conveyor belt production lines and excellent production equipment.

Advanced technical strength

More than 500 engineering cases, advanced design and production processes, reliable product quality, and consistent customer praise.

Professional technical team

We have a professional scientific research team with industry experts and technicians with many years of experience.

Perfect after-sales service

A professional after-sales team is online 7*24 hours to provide you with star-rated intimate service, more peace of mind.

Production Capacity

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have pre-shipment inspection procedures?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

What are the payment terms?

Wire transfer or Letter of Credit, Western Union, Alipay, etc.

Can I have my own customized product?

Yes. OEM and ODM services are available, including design, logo, and packaging.

Extra-wide conveyor belt

Let our industry experts tailor a solution for you,Contact us!

Category

Inquiry Now

Filling in your phone number and email information will help us contact you in time and quickly resolve the issues you raise.