Underground PVG solid-core flame-retardant conveyor belt

Let our industry experts tailor a solution for you,Contact us!

- Product Description

-

The overall core flame-retardant conveyor belt (PVC-PVG) is mainly used in underground coal mines. Features of this belt include: no delamination, low elongation, impact resistance, and tear resistance. According to different structures, it can be divided into PVC type (plastic surface) and PVG type (rubber surface added on the basis of PVC) full-core flame-retardant belts, complying with the MT914-2002 standard.

(1) PVC flame-retardant conveyor belts are suitable for material conveying under dry conditions with an inclination angle of less than 16 degrees.

(2) PVG flame-retardant conveyor belts are suitable for conveying wet materials with an inclination angle of less than 20 degrees.1. Model N/mm (tensile strength):

Level Level 4 Level 5 Level 6 Level 7 Level 8 Level 9 Level 10 Model 680s 800s 1000s 1250s 1400s 1600s 1800s

2. Flame-retardant performance:

(1) Roller abrasion: The surface temperature of the roller is no more than 325℃.

(2) Blowtorch burning: The average flameless time of the full-thickness specimen without a blowtorch is no more than 3.0S, and the average flameless time of the covering layer is no more than 5.0S.

(3) Propane burning: The undamaged length is greater than 250mm

3. Surface resistance:

The average value of the upper and lower surfaces is no more than 3.0 × 108Ω

4. Performance:

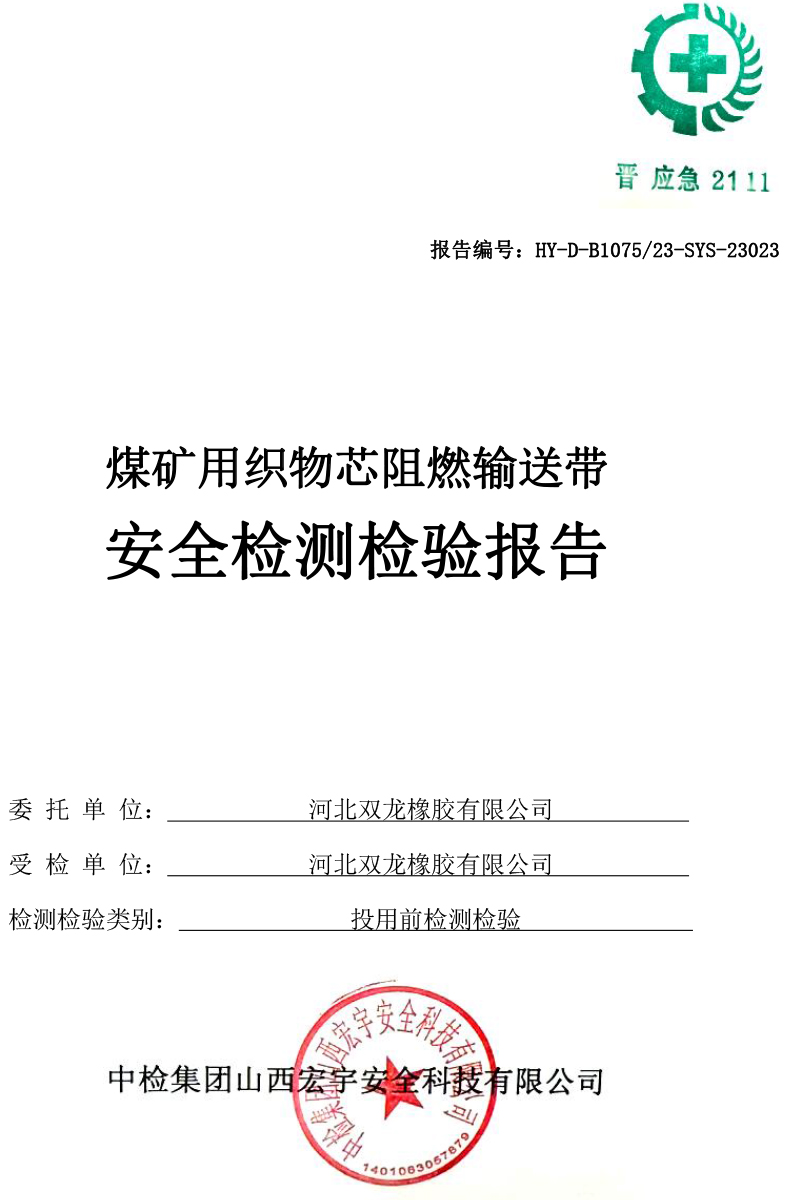

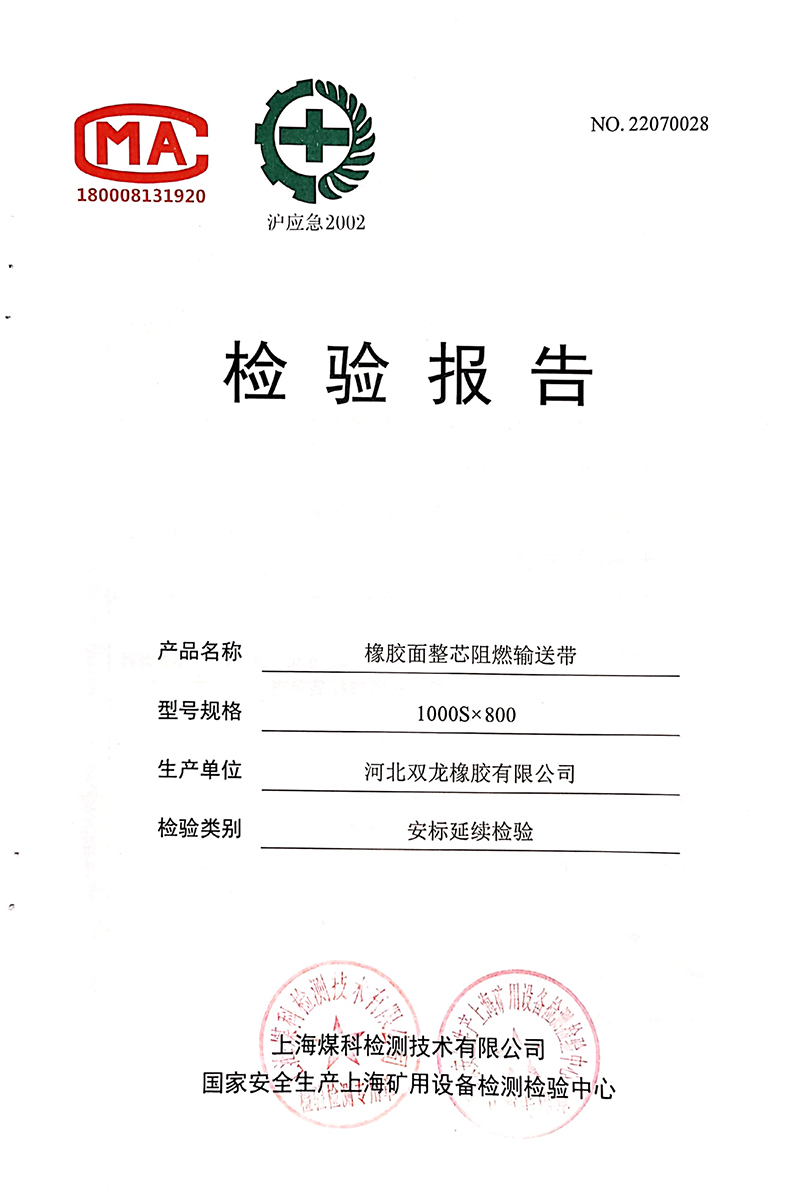

This conveyor belt has passed flame-retardant tests and electrostatic tests and has obtained a qualified certificate, coal mine safety mark, and customer recognition.

5. Mechanical properties:

Excellent mechanical properties, providing users with a longer service life and economical installation and use.

Service life: The service life of the belt is determined by the following factors: the warp and weft filaments and the densely woven covering cotton core; the specially formulated PVC material makes the core and cover rubber achieve high bonding strength; specially formulated cover rubber; thus making the belt impact-resistant, tear-resistant, and wear-resistant.

This product has excellent properties such as wear resistance, anti-static, waterproof, flame retardancy, and high strength of the full-core flame-retardant belt, and is more cost-effective and cheaper than other flame-retardant conveyor belts. It is one of the more common and popular types of flame-retardant conveyor belts at home and abroad, especially suitable for underground conveying places with small slopes such as coal mines.

6. Product structure:

This product uses a whole core as the skeleton material, which is made by impregnation and coating with PVC materials with anti-static and flame-retardant properties.

7. Joint performance:

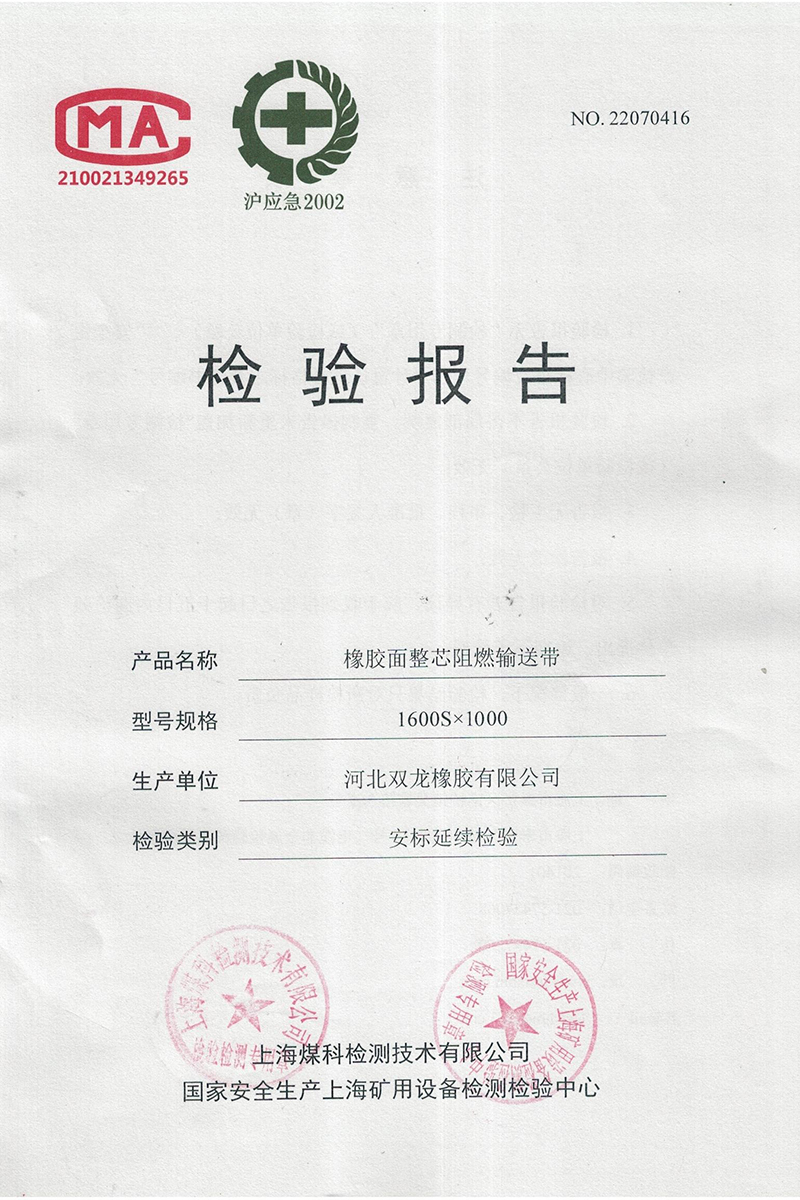

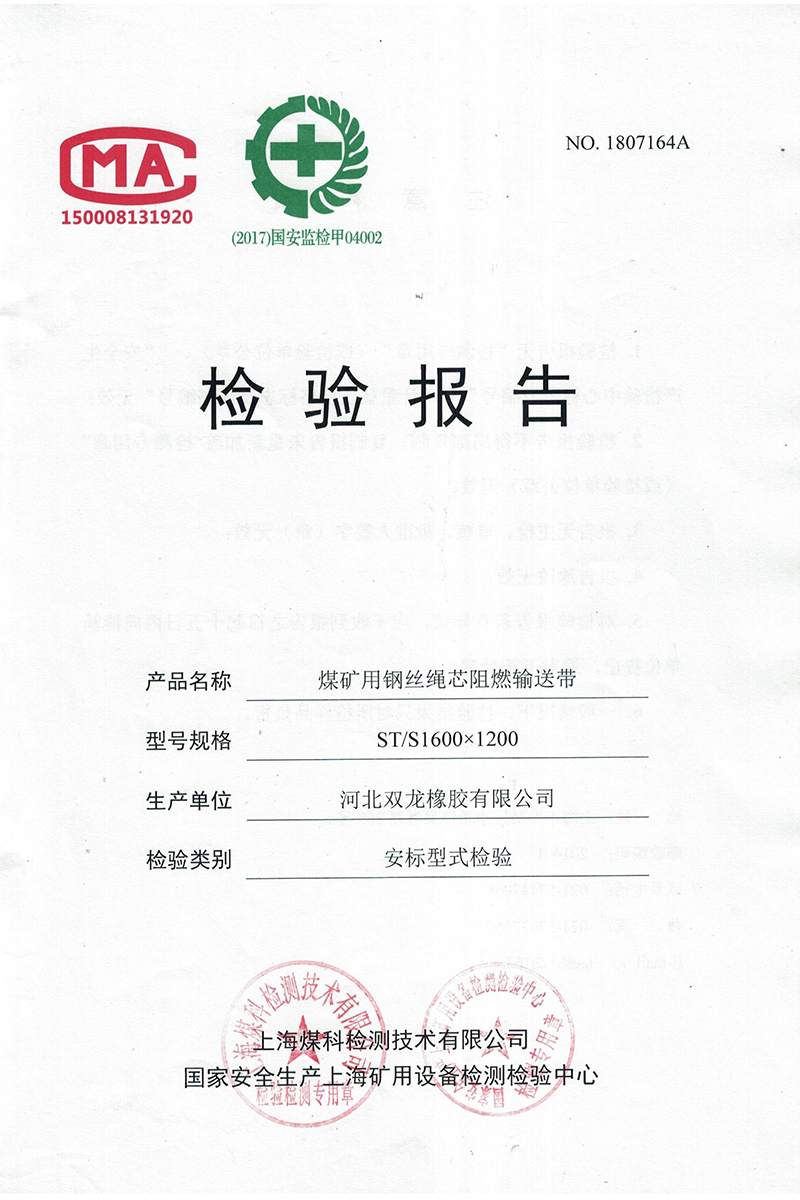

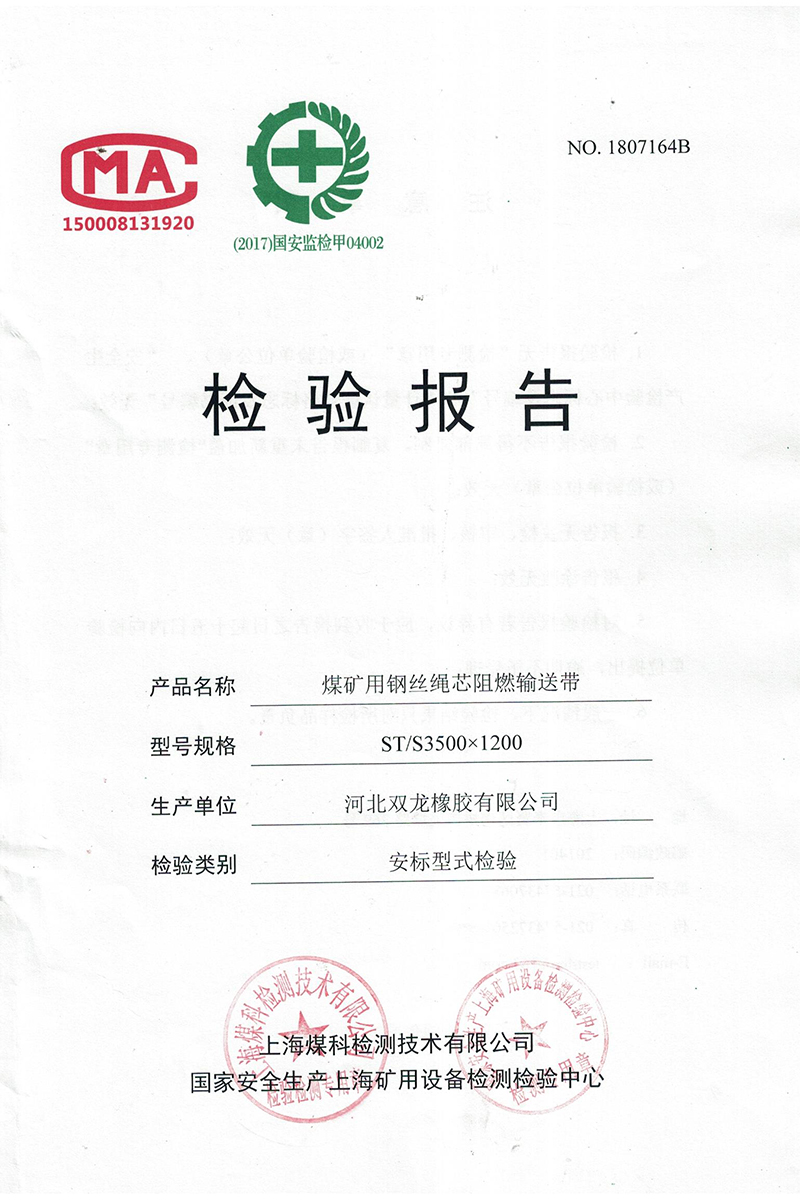

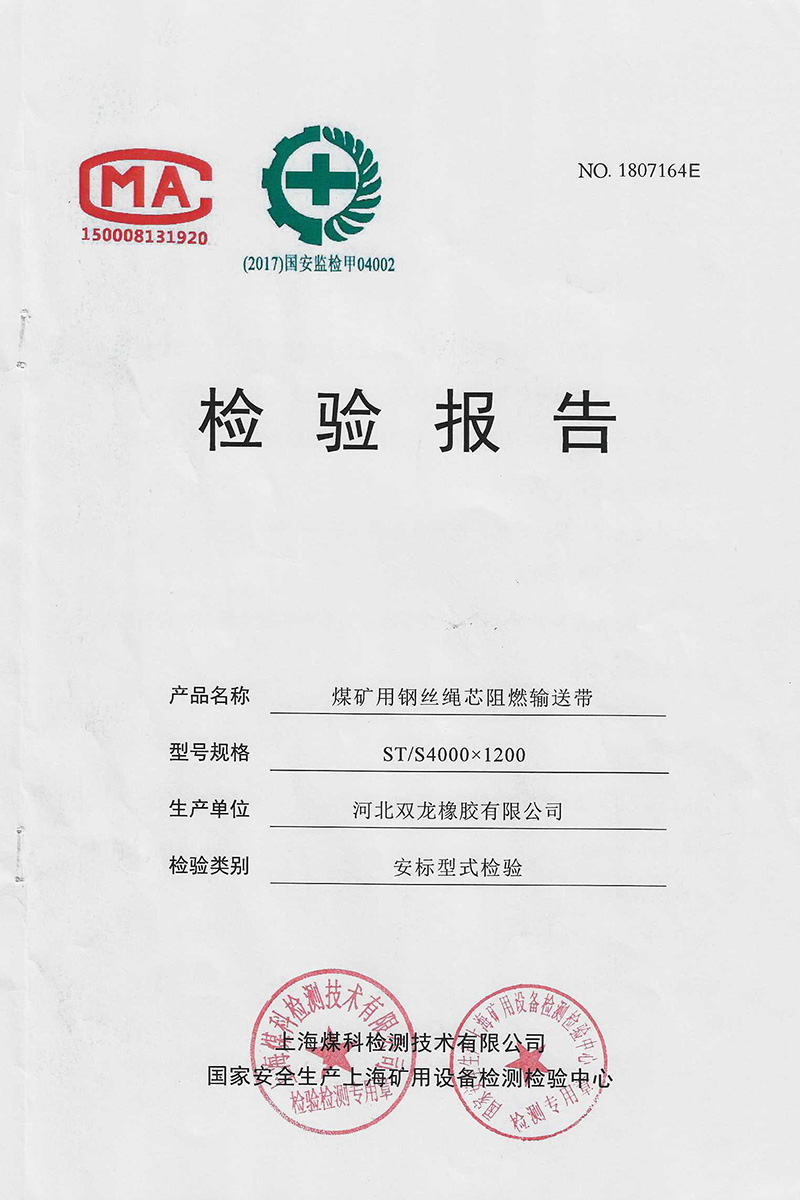

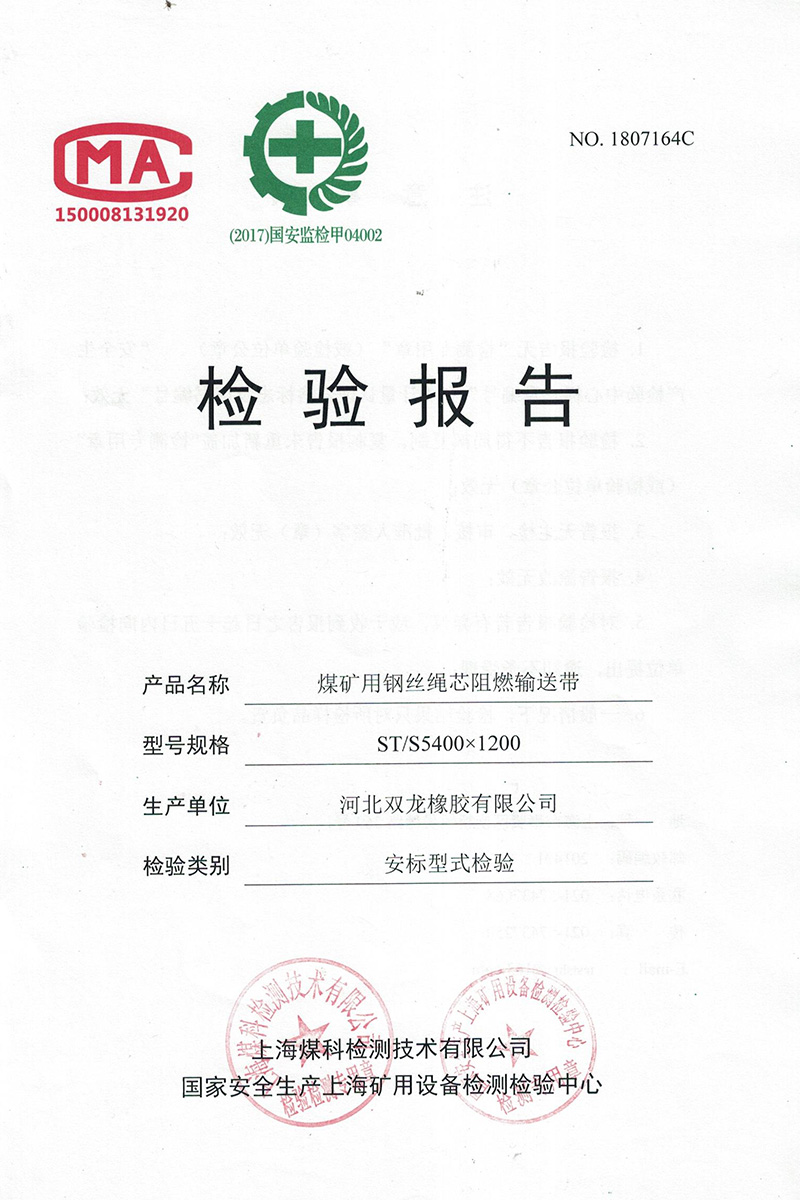

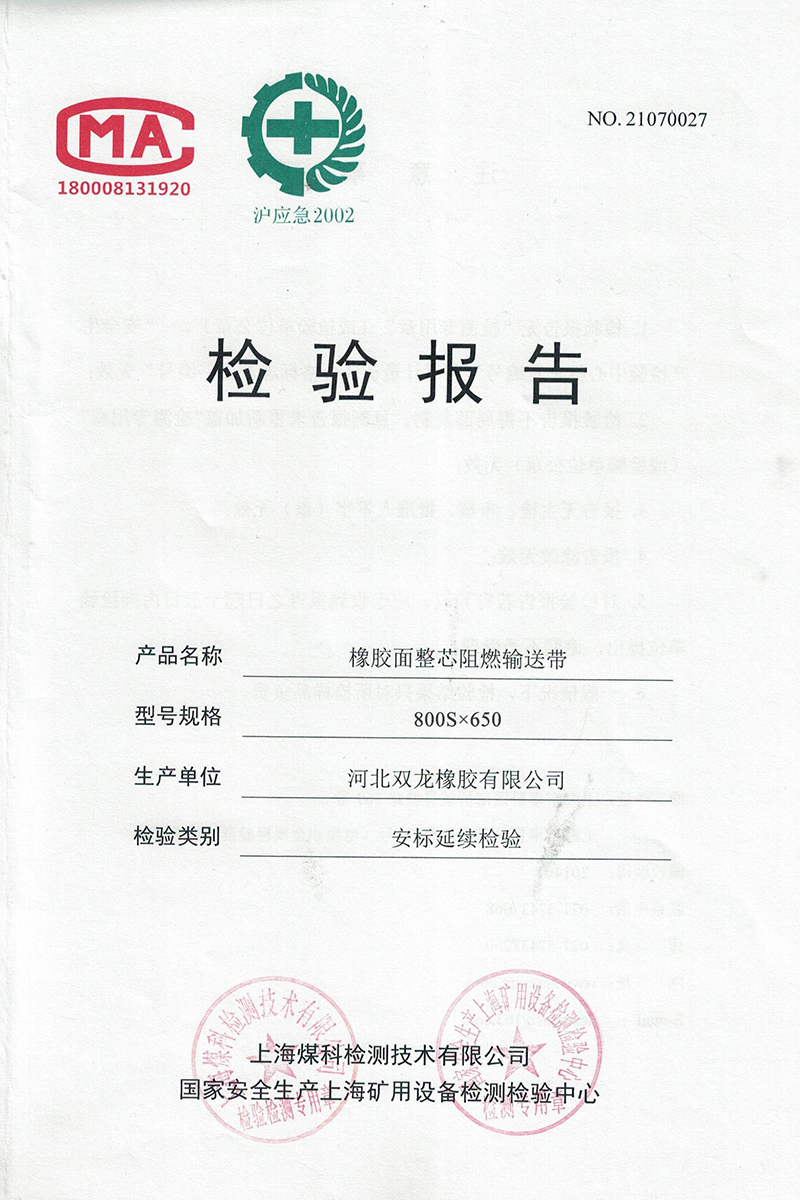

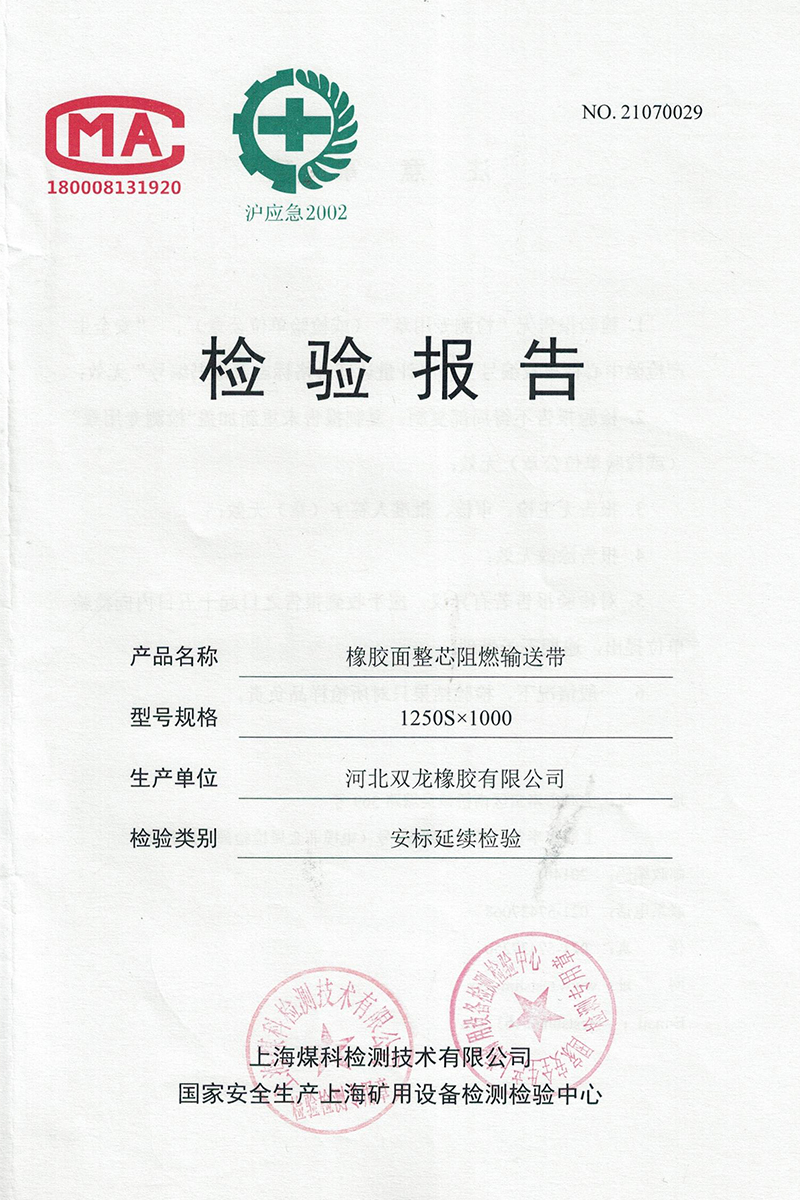

According to the belt strength and core structure, mechanical buckle connection is used, and its strength can reach 50%-100% of the belt strength; vulcanized joints are used, and their strength can reach 60%-100% of the belt strength. Various types of joints can meet the different needs of customers and ensure the safe and efficient operation of the system.Average surface resistance ≤3×108Ω Roller friction performance Permissible higher temperature ≤325℃, and no flaming or flameless combustion is required. Alcohol blowtorch burning test Average value ≤3S (with covering layer), single value ≤10S (with covering layer) Average value ≤5S (without covering layer), single value ≤15S (without covering layer) Propane roadway combustion performance Unburned retained segment length >250mm High-energy roadway propane combustion test Full-width undamaged length segment >2250 Product specifications Tensile strength (N/mm) Elongation at break (%) Tear strength (N) ≥ Longitudinal ≥ Transverse ≥ Longitudinal ≥ Transverse ≥ 680S 680 265 15 18 1090 800S 800 280 15 18 1180 1000S 1000 300 15 18 1180 Test report

Our Advantages

Excellent production equipment

The company has introduced multiple conveyor belt production lines and excellent production equipment.

Advanced technical strength

More than 500 engineering cases, advanced design and production processes, reliable product quality, and consistent customer praise.

Professional technical team

We have a professional scientific research team with industry experts and technicians with many years of experience.

Perfect after-sales service

A professional after-sales team is online 7*24 hours to provide you with star-rated intimate service, more peace of mind.

Production Capacity

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have pre-shipment inspection procedures?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

What are the payment terms?

Wire transfer or Letter of Credit, Western Union, Alipay, etc.

Can I have my own customized product?

Yes. OEM and ODM services are available, including design, logo, and packaging.

Underground PVG solid-core flame-retardant conveyor belt

Let our industry experts tailor a solution for you,Contact us!

Inquiry Now

Filling in your phone number and email information will help us contact you in time and quickly resolve the issues you raise.