Product Categories

Contact Us

E-mail:

Aaron@bestconveyoring.com

Tel/WhatsApp:

+86 15230282222

Address:

Duikan Zhuang Rubber Industrial Park, Li County, Hebei Province

Roller conveyors are common material handling devices. They feature simple structures, high reliability, and convenient maintenance. A roller conveyor mainly consists of a drive roller, frame, support, and drive unit. Roller conveyor structures are categorized by drive type (powered, unpowered, electric roller) and layout (horizontal, inclined, and curved).

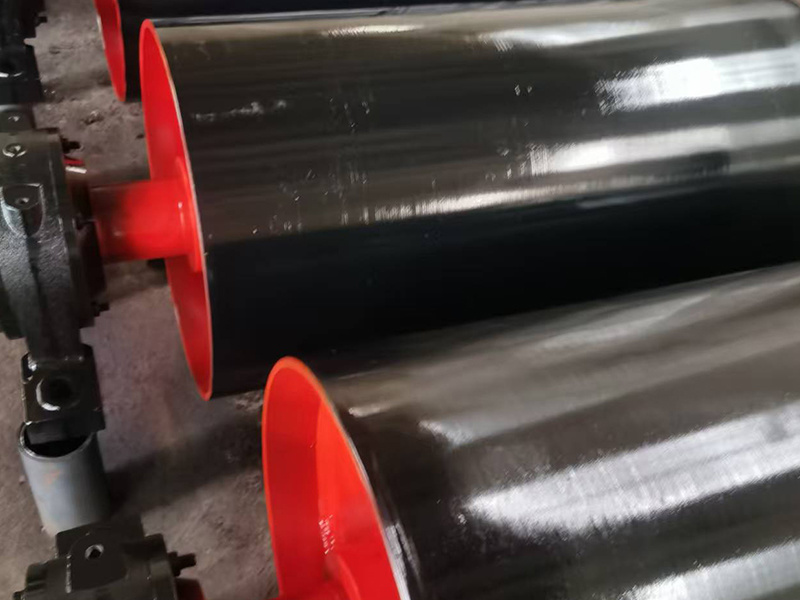

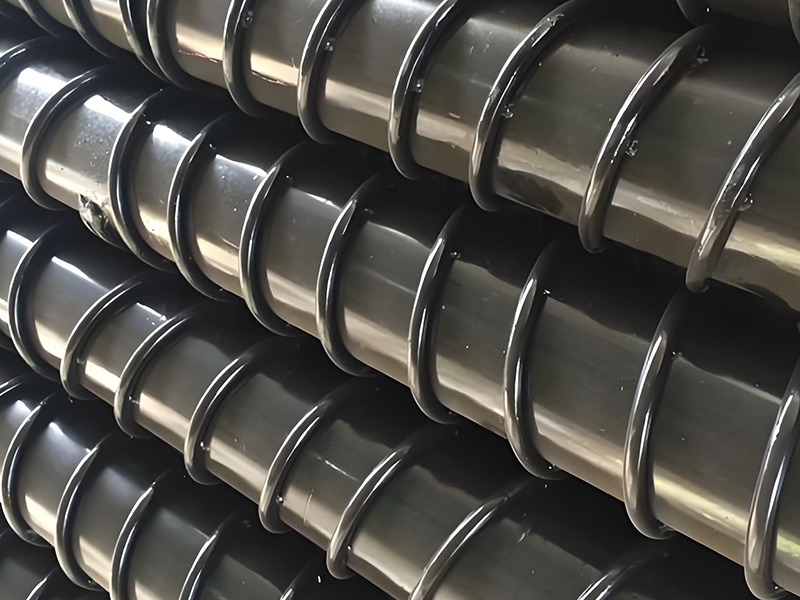

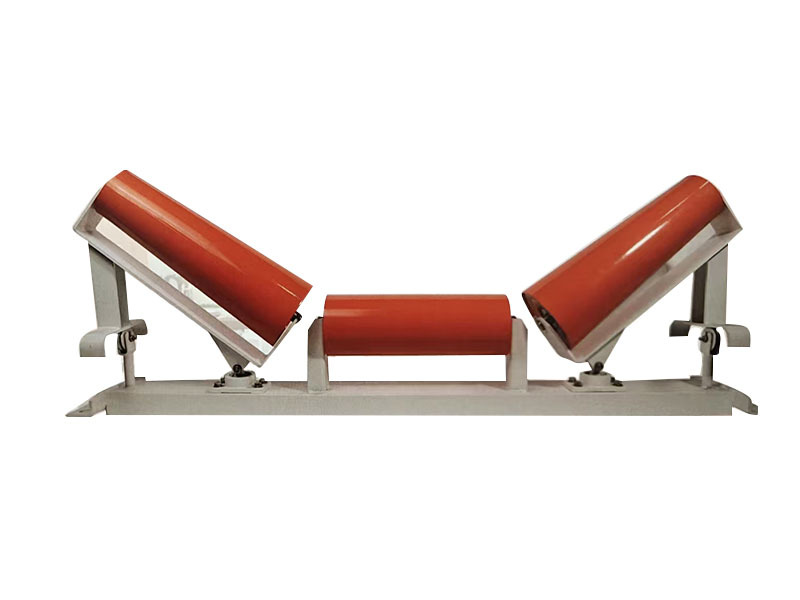

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Roller conveyors are common material handling devices. They feature simple structures, high reliability, and convenient maintenance. A roller conveyor mainly consists of a drive roller, frame, support, and drive unit. Roller conveyor structures are categorized by drive type (powered, unpowered, electric roller) and layout (horizontal, inclined, and curved).

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idler roller group (self-aligning)

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

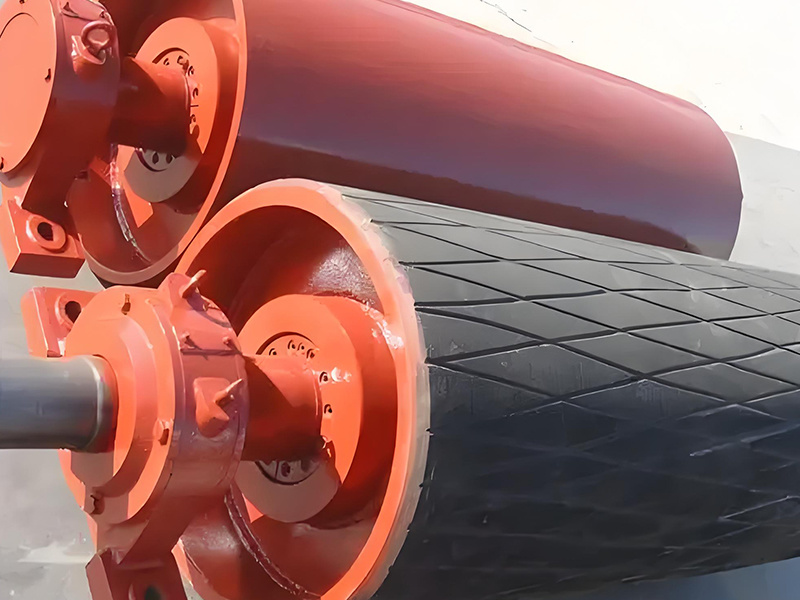

Diamond plate rubber is a wear-resistant rubber material commonly used for roller covering. Its unique diamond pattern design increases friction and disperses impact force. It features high wear resistance, high elasticity, and acid and alkali resistance. One-piece molding simplifies installation and is suitable for material transportation scenarios such as coal and mining, effectively improving transportation efficiency and extending equipment lifespan.

The roller pulley is an important component and part of the belt conveyor transport system. Enclosing the roller pulley can effectively improve the operation of the transport system, protect the metal roller pulley from wear, prevent belt slippage, and ensure synchronous operation of the roller pulley and belt.

Roller conveyors are common material handling devices. They feature simple structures, high reliability, and convenient maintenance. A roller conveyor mainly consists of a drive roller, frame, support, and drive unit. Roller conveyor structures are categorized by drive type (powered, unpowered, electric roller) and layout (horizontal, inclined, and curved).

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.

Idlers are important components of belt conveyors. They support the conveyor belt and the material being conveyed, reducing the running resistance of the conveyor belt and ensuring that the conveyor belt sag does not exceed the specified limit, thus guaranteeing smooth operation. Their structure consists of a roller body, bearings, seals, etc. According to their use, they are divided into trough, parallel, and self-aligning types, and are widely used in mining, ports, power plants, and other fields.