Roller group

Let our industry experts tailor a solution for you,Contact us!

Category

- Product Description

-

• Drive roller function: Transmits torque from the drive device to the conveyor belt. Drive rollers are classified into light, medium, and heavy types according to their load-bearing capacity. Various shaft diameters and center distances are available for the same type of roller. The roller surface has a polished steel surface, diamond pattern, and herringbone pattern rubber covering.

• Return rollers (tail rollers) are also called return rollers and are used to guide the conveyor belt back to the drive roller. These tail rollers may have built-in bearings or be fixed in external bearing housings, usually located at the end of the conveyor frame.

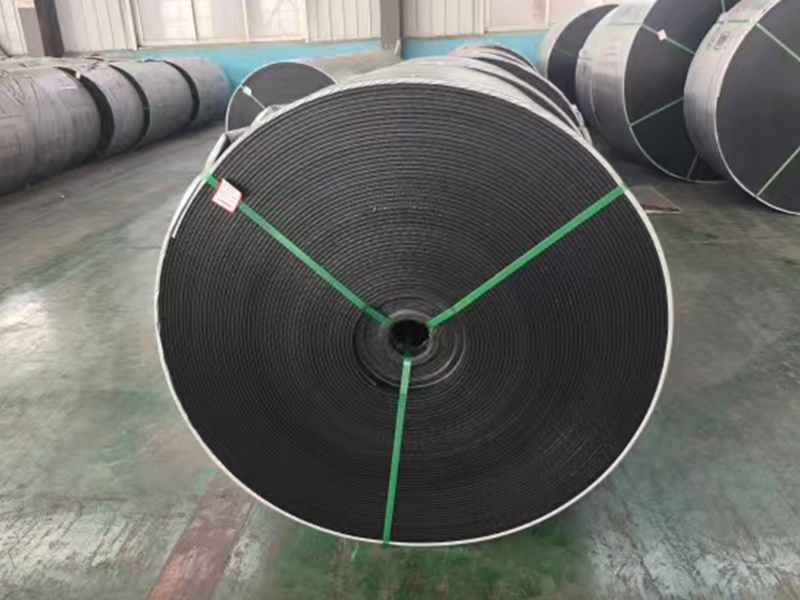

Conveyor rollers are a common material handling device, characterized by their simple structure, high reliability, and ease of use and maintenance. Conveyor rollers mainly consist of drive rollers, frames, supports, and drive units. The structural forms of roller conveyors are divided into powered, unpowered, and electric rollers according to the drive form, and into horizontal, inclined, and turning conveyors according to the layout form.

The drive roller is the core component of the roller conveyor, used to support and drive the conveyor belt. It consists of a steel pipe and bearings, and is usually hot-dip galvanized to prevent corrosion. The conveyor belt is the component of the roller conveyor used to convey materials, usually made of rubber, nylon, etc. Different types and specifications of conveyor belts can be selected according to the characteristics of the material and the conveying distance.Conveyor Roller Specifications and Technical Parameters

Drive Roller (Rollers Head Pulley) (smooth surface or textured non-slip surface) Conveyor Belt Width (mm) Standard Roller Diameter (mm) Roller Length (mm) 500 500 The length of the pulley depends on the width of the conveyor belt 650 500-630 800 630-1000 1000 800-1150 1200 800-1150 1400 1000-1350 1600 1150-1600 1800 1150-1800 2000 1350-2000 2200 1600-2200 2400 1800-2400 Material: Tail rollers are usually made of steel, which can be low carbon steel or stainless steel, to withstand wear and tear from continuous use. Application: Tail rollers are used in conveyor systems to provide tension for the conveyor belt and ensure correct belt tracking. They are typically installed at the tail end of the conveyor, opposite the head roller. Structure: Tail rollers are cylindrical with a smooth surface to facilitate conveyor belt operation. They are typically mounted on a shaft and supported by bearings. Bearing Type: Bearings used in tail rollers are typically self-aligning ball bearings or spherical roller bearings, capable of withstanding misalignment and axial loads. Roller Type: Tail rollers come in various types, including standard, heavy-duty, spiral, and winged types. The required type depends on the specific application and load capacity of the conveyor system. Transportation and Packaging: Tail rollers are usually transported in wooden crates or on pallets to prevent damage during transportation. Samples: Some manufacturers may provide tail roller samples upon request to help customers evaluate their quality and suitability. Customization: Tail rollers can be customized for specific conveyor systems, including dimensions, shaft diameter, and bearing type. Packaging Details

1. Waterproof nylon packaging, iron frame or wooden crate and pallet.

2. Standard and appropriate export packaging.

3. Customized packaging is available upon customer request.

Frequently Asked Questions

1. Can I customize conveyor belts and rollers to meet my business needs?

►Yes, we are a professional manufacturer of customized conveyor belts and rollers , focused on providing customized conveyor belt and roller solutions. We work closely with our customers to customize products such as belt width, thickness, material composition, and various qualities based on their specific operational requirements. This ensures that our conveyor belts perform optimally in various industrial environments.

2. What payment methods do you accept?

►We offer flexible payment methods to meet customer needs. Commonly used payment methods include Telegraphic Transfer (T/T) and Letter of Credit (L/C) ,especially for large orders. We can also negotiate other payment methods based on mutual agreement.

3. What after-sales service do you provide? How do you guarantee your quality?

►We provide comprehensive after-sales service support, including 24/7 technical support, installation assistance, and maintenance advice . We also provide regular follow-up services to ensure smooth product operation and long-term customer satisfaction! We have an in-house testing laboratory and adhere to the principle that products must pass inspection before leaving the factory! For many years, we have been one of the suppliers to internationally renowned companies, and our customers are located in various countries and regions, including mining, stone crushing, sand washing, ports, power, metallurgy, chemical, coal, steel plants, cement plants, and construction industries. Our excellent quality is widely praised.

4. How do I place an order? What is the delivery time?

►You can contact us to place an order via WeChat, WhatsApp, phone, email, and website. For regular models, delivery is 5-7 days ,The delivery time for other customized products depends on the product type and customization requirements.

5. Can I get samples to check and test?

►Yes, samples can be sent for testing before bulk orders. Samples are created according to customer requirements, allowing customers to evaluate the performance of the belts and rollers.

6. Can I print my LOGO on the conveyor belt products?

Why choose our conveyor belts and rollers?

1. Engineering Design and Consulting

Our conveyor belts and rollers are ideal for handling various heavy and abrasive materials in bulk material handling, successfully meeting the needs of various industries, including stone crushing and screening, sand washing, fertilizer, grain conveying, steel plants, power plants, cement plants, metallurgy, coal, ports and docks, construction, and more. As a one-stop conveyor engineering manufacturer, we also provide excellent solutions for material handling problems and after-sales service for various applications.

2. Excellent Customer Service

We specialize in the production of heavy-duty (nylon, EP polyester, EE, NN) multi-layer fabric core rubber conveyor belts and conveyor rollers, steel cord conveyor belts, corrugated edge conveyor belts, bucket elevator conveyor belts, and patterned herringbone conveyor belts, ring conveyor belts, etc. As a high-quality manufacturer, supplier, and exporter in China, we focus on providing customers with high-quality conveyor belts and professional services.

3. Customization

OEM support, meeting all your needs, regardless of size, even if you only have an idea, we will help you realize it.

We have a strong R&D team that can develop and produce products according to customer-provided drawings or samples.

4. Cost-effectiveness

Same quality, lower price; same price, better quality; fast production cycle; short time; efficient and durable; reliable quality. We are based in the mid-to-high-end market, and our products meet international standards.

Our Advantages

Excellent production equipment

The company has introduced multiple conveyor belt production lines and excellent production equipment.

Advanced technical strength

More than 500 engineering cases, advanced design and production processes, reliable product quality, and consistent customer praise.

Professional technical team

We have a professional scientific research team with industry experts and technicians with many years of experience.

Perfect after-sales service

A professional after-sales team is online 7*24 hours to provide you with star-rated intimate service, more peace of mind.

Production Capacity

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have pre-shipment inspection procedures?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

What are the payment terms?

Wire transfer or Letter of Credit, Western Union, Alipay, etc.

Can I have my own customized product?

Yes. OEM and ODM services are available, including design, logo, and packaging.

Roller group

Let our industry experts tailor a solution for you,Contact us!

Category

Inquiry Now

Filling in your phone number and email information will help us contact you in time and quickly resolve the issues you raise.