Product Categories

Contact Us

E-mail:

Aaron@bestconveyoring.com

Tel/WhatsApp:

+86 15230282222

Address:

Duikan Zhuang Rubber Industrial Park, Li County, Hebei Province

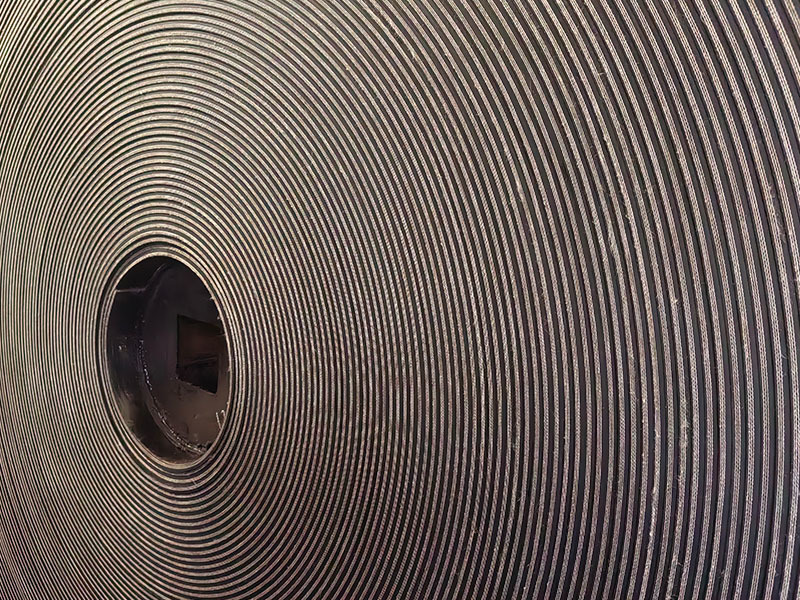

Nylon and rubber conveyor belts are especially suitable for mining, stone crushing and screening, sand washing, ports and docks, power, metallurgy, chemical industry, coal, steel plants, cement plants, construction and other industries. They are suitable for most medium/long distances, high loads, and high-speed material conveying conditions.

High wear-resistant conveyor belt

High wear-resistant and energy-saving multi-layer fabric core (nylon/EP polyester/NN/EE) rubber conveyor belts are especially suitable for mining stone crushing and screening, sand washing, ports and docks, chemical fertilizers, power, metallurgy, chemical industry, steel plants, cement plants, coal, docks, construction and other industries. They feature energy saving and wear resistance, and are suitable for most short/medium/long distances, high loads, and high-speed material conveying conditions.

Heat-resistant (EP) polyester conveyor belt

Heat-resistant conveyor belts are mainly used for conveying high-temperature materials, such as sintered ore, hot coke, cement clinker, and hot castings. According to the main manifestations of damage and loss of conveying capacity of heat-resistant belts and different heat-resistant levels, ethylene propylene rubber or styrene-butadiene rubber is used as the cover rubber; high-strength and high-permeability polyester canvas or cotton canvas is used as the strong layer. Heat-resistant glass cloth can be laid between the cover rubber and the carcass layer to improve the service life of the heat-resistant belt. According to customer requirements, it can be made into a ring belt.

Flower patterned herringbone conveyor belt

The patterned conveyor belt has a wide range of uses. With a material conveying angle of 0°--45°, it prevents material slippage and improves conveying efficiency. It can be used to convey cement clinker, lime, sand and gravel, domestic or industrial waste, coal, and various bagged items. It is widely used in the coal, mining, power, chemical, steel, and grain industries.

Wire rope conveyor belts have proven to be a very reliable and cost-effective method for conveying bulk materials in long-distance conveyors. We offer laterally reinforced belts, belts with embedded sensor coils, and standard wire rope conveyor belts.

Upper convex inverted V-shaped pattern conveyor belt

The patterned conveyor belt has a wide range of uses. With a material conveying angle of 0°--45°, it prevents material slippage and improves conveying efficiency. It can be used to convey cement clinker, lime, sand and gravel, domestic or industrial waste, coal, and various bagged items. It is widely used in the coal, mining, power, chemical, steel, and grain industries.

The edge conveyor belt covering is made of nitrile rubber with excellent oil resistance, featuring oil resistance, heat resistance, and corrosion resistance. Suitable for conveying oily materials or in environments where it contacts various working oils. Both sides are neat, running stably without deviation, accurately positioning materials. Made of high-strength wear-resistant material, it is resistant to pulling and tearing, and has strong load-bearing capacity. Adaptable to high-temperature and chemical complex environments. The surface is anti-slip and anti-static, safe and reliable, and easy to maintain and replace, effectively improving conveying efficiency. Reinforced materials can be selected according to different customer needs.

Overall steel mesh/anti-tear mesh tear-resistant conveyor belt

The tear-resistant and impact-resistant conveyor belt uses a steel wire mesh or nylon high-strength, high-elongation chemical fiber rope as the carcass layer, which has excellent tear resistance, effectively prevents puncture by foreign objects, and has excellent heat resistance.

Highly wear-resistant conveyor belt

High-strength conveyor belts are suitable for mines, ports, metallurgy, power, chemical, cement plants, steel plants, coal, building materials, and other occasions with large, sharp, hard objects. They are suitable for most medium/long distances, high loads, large sharp and hard objects, and high-speed conveying operations in industrial and mining conditions.

A continuous loop conveyor belt is a conveyor belt formed into a seamless loop during the production process. Its key feature is that the core has no joints, preventing premature damage at the joint and extending its service life.