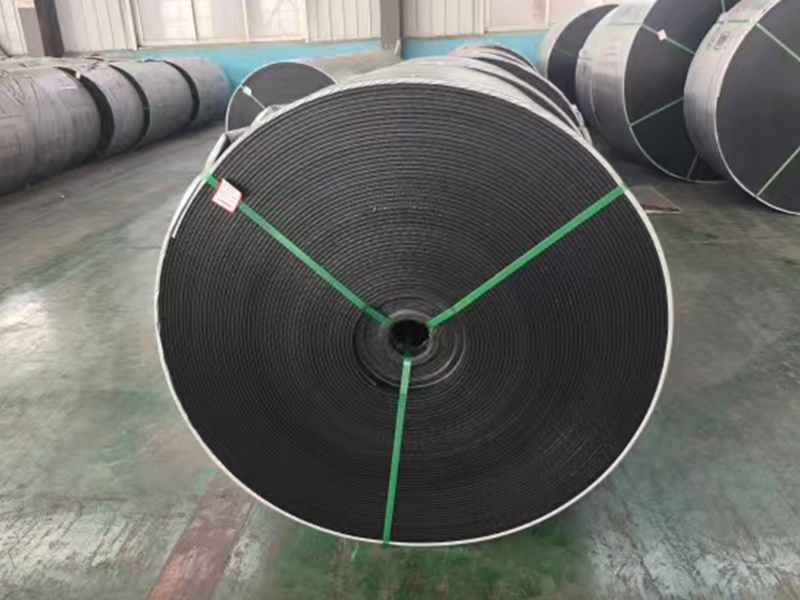

Flower patterned herringbone conveyor belt

Let our industry experts tailor a solution for you,Contact us!

- Product Description

-

Features

Patterned conveyor belts are widely used, with material conveying angles ranging from 0° to 45°. The patterned conveyor belt prevents material slippage and improves conveying efficiency. It can be used to convey cement clinker, lime, sand and gravel, domestic or industrial waste, coal, and various bagged items. Widely used in coal, mining, power, chemical, steel, and grain industries.

Uses

The cover rubber of a general conveyor belt is flat. To increase the conveying angle and prevent material slippage, the conveyor belt cover rubber can be made with a patterned design. This type of conveyor belt with a patterned cover rubber is called a patterned conveyor belt.

Suitable for conveying powdery, granular, and small-piece materials at angles ≤45°. It can also convey packaged materials and is widely used in coal mining, power, chemical, and grain industries.

Pattern types: herringbone, pit type, diamond, convex herringbone, etc.

Belt width: 300mm~2500mm

Shallow patterned conveyor belt (pattern depth less than 10mm, conveying angle 20℃~30℃)

Deep patterned conveyor belt (pattern depth more than 10mm, conveying angle 30℃~45℃)Note: Conventional pattern models are "V-type, Y-type, C-type, multi-V-type, G-type, T-type" Any pattern design is supported! The pattern shape can be designed according to user requirements, customized pattern design!

Cover rubber quality/grade standard performance parameters

German standard DIN-22102 Grade Tensile strength ≥Ma Elongation at break ≥M% Abrasion loss ≥mm 3 Inter-ply adhesion strength (N/mm) Adhesion strength between cover and carcass (/mm) Cover thickness 0.8~1.5mm Cover thickness >1.5mm W 18 400 90 ≥5 3.5 4.5 X 25 450 120 Y 20 400 150 Z 15 350 250 British Standard BS 490 Grade Tensile strength ≥Ma Elongation at break ≥M% Abrasion loss ≥mm 3 Inter-ply adhesion strength (N/mm) Adhesion strength between cover and carcass (/mm) Cover thickness 0.8~1.5mm Cover thickness >1.5mm M 24 450 - ≥5.25 3.15 4.5 N 17 400 - Australian Standard AS 1332-2000 Grade Tensile strength ≥Ma Elongation at break ≥M% Abrasion loss ≥mm 3 Inter-ply adhesion strength (N/mm) Adhesion strength between cover and carcass (/mm) Cover thickness 0.8~1.5mm Cover thickness >1.5mm A 17 400 70 6 4 4.8 E 14 300 - F 14 300 - M 24 450 125 N 17 400 200 S 14 300 250 S* 12 300 250 South African SANS 1173:2005 Grade Tensile strength ≥Ma Elongation at break ≥M% Abrasion loss ≥mm 3 Inter-ply adhesion strength (N/mm) Adhesion strength between cover and carcass (N/mm) A 18 400 90 ≥7 ≥5 X 25 450 120 M 24 450 150 N 20 400 250 Specifications and technical parameters of multi-layer fabric core conveyor belts

Fabric type Fabric structure Fabric model Rubber thickness (mm/p) Strength series (N/mm) Cover rubber thickness Width range (mm) Warp Weft 2 layers 3 layers 4 layers 5 layers 6 layers Top cover Bottom cover Nylon

EP polyester

NN

EE

Nylon Nylon Nylon/EP polyester/NN/EE-100 1.00 200 300 400 500 600 0-12 0-10 300-2500 Nylon/EP polyester/NN/EE-125 1.05 250 375 500 625 750 Nylon/EP polyester/NN/EE-150 1.10 300 450 600 750 900 Nylon/EP polyester/NN/EE-200 1.20 400 600 800 1000 1200 Nylon/EP polyester/NN/EE-250 1.40 500 750 1000 1250 1500 Nylon/EP polyester/NN/EE-300 1.60 600 900 1200 1500 1800 Bonding strength and elongation performance meet the following table

Belt core material Bonding strength Elongation performance Inter-ply N/mm Adhesion strength between cover and carcass N/mm Total thickness longitudinal elongation at break Total thickness longitudinal reference force elongation Cover thickness ≤1.5mm Cover thickness ≥1.5mm Polyester canvas ≥5 ≥4.5 ≥5 ≥10% ≤4%6 Shipping scenarios

Our Advantages

Excellent production equipment

The company has introduced multiple conveyor belt production lines and excellent production equipment.

Advanced technical strength

More than 500 engineering cases, advanced design and production processes, reliable product quality, and consistent customer praise.

Professional technical team

We have a professional scientific research team with industry experts and technicians with many years of experience.

Perfect after-sales service

A professional after-sales team is online 7*24 hours to provide you with star-rated intimate service, more peace of mind.

Production Capacity

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have pre-shipment inspection procedures?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

What are the payment terms?

Wire transfer or Letter of Credit, Western Union, Alipay, etc.

Can I have my own customized product?

Yes. OEM and ODM services are available, including design, logo, and packaging.

Flower patterned herringbone conveyor belt

Let our industry experts tailor a solution for you,Contact us!

Inquiry Now

Filling in your phone number and email information will help us contact you in time and quickly resolve the issues you raise.