Rubber pad/rubber sheet/rubber block

Let our industry experts tailor a solution for you,Contact us!

- Product Description

-

Category

Rubber sheets can be categorized according to different standards, such as application, composition, hardness, surface treatment, etc.

Rubber sheets, rubber blocks, and rubber pads are all made of rubber. Due to their excellent elasticity, wear resistance, corrosion resistance, insulation, and other characteristics, they are widely used in various fields and play multiple roles, as detailed below:

Industrial Field

• Shock absorption and buffering: Installing rubber pads or blocks at the bottom of large machinery can effectively reduce vibrations and noise generated during operation, protecting the equipment and preventing impact on the surrounding environment.

• Sealing: Rubber sheets can be used to make various sealing gaskets and washers, installed at the joints of pipes and containers to prevent leakage of liquids and gases.

• Insulation: Rubber sheets with good insulation properties are often used in electrical equipment as insulation pads or shields to protect operators and prevent electric shock.

Construction Field

• Waterproofing: Rubber sheets can be used as waterproofing materials for buildings, basements, etc., effectively preventing the penetration of rainwater and groundwater, and extending the service life of the building.

• Seismic isolation: Rubber seismic isolation bearings, made of multiple layers of rubber and steel plates alternately laminated and vulcanized, are used in the basic structures of some buildings. They can effectively absorb and dissipate seismic energy during earthquakes, reducing damage to buildings.

Daily Life Field

• Anti-slip: Placing rubber mats in bathrooms and kitchens, where slipping is easy, increases friction due to the textured surface, providing anti-slip protection.

• Buffering and protection: Rubber mats are used in some sports venues, such as weightlifting areas in gyms and children's playgrounds, to provide cushioning in case of falls or dropped objects, reducing injuries.

Other Fields

• In the automotive industry: Rubber pads are used in vehicle suspension systems and engine mounts to reduce vibrations and noise, improving driving comfort.

• In the aerospace field: Rubber products are used in aircraft landing gear and engine compartments to provide shock absorption, sealing, and insulation, ensuring safe flight.

Categorization by Application

Insulating rubber sheet: Mainly used for electronic and electrical insulation, it has high insulation performance and good electrical properties, effectively preventing leakage and short circuits. In addition, insulating rubber sheets are also characterized by high temperature resistance, aging resistance, and oil resistance.

Sealing rubber sheet: Mainly used for various sealing applications, such as warehouses and ship holds. It has good resilience, insulation, water resistance, and plasticity, effectively preventing leakage and dust entry.

Buffering rubber sheet: Mainly used to reduce impact and vibration, such as in vehicles, trains, and aircraft as shock-absorbing materials. Buffering rubber sheets are usually made of high-elasticity materials and can effectively absorb impact energy.

Anti-slip rubber sheet: Mainly used for ground anti-slip applications, it has a high friction coefficient and good wear resistance, effectively preventing slips and falls.

Categorization by Composition

Natural rubber sheet: Made primarily from natural rubber, it has good elasticity and insulation properties, suitable for various sealing and buffering applications.

Synthetic rubber sheet: Made from synthetic rubber materials, it has better high-temperature resistance, oil resistance, and aging resistance, suitable for more demanding working environments.

Categorization by Hardness

Hard rubber sheet: Higher hardness, good insulation and sealing properties, suitable for various sealing and insulation applications.

Soft rubber sheet: Lower hardness, better buffering and anti-slip properties, suitable for various shock absorption and anti-slip applications.

Categorization by Surface Treatment

Ordinary rubber sheet: Rubber sheet with untreated surface, suitable for general applications.

Anti-slip rubber sheet: Rubber sheet with anti-slip surface treatment, increasing the friction coefficient, suitable for applications requiring anti-slip properties.

Oil-resistant rubber sheet: Rubber sheet with oil-resistant surface treatment, increasing resistance to oily substances, suitable for applications with oil stains.

Acid and alkali-resistant rubber sheet: Rubber sheet with acid and alkali-resistant surface treatment, increasing resistance to acids and alkalis, suitable for applications with acids and alkalis.

Categorization by Thickness

Thin rubber sheet: Relatively thin, usually less than 1mm, suitable for applications requiring lightweight materials.

Medium-thickness rubber sheet: Moderate thickness, usually between 1mm and 5mm, suitable for general purpose applications.

Thick rubber sheet: Relatively thick, usually more than 5mm, suitable for applications requiring thicker materials, such as tire manufacturing.

Characteristics

Rubber sheets have various characteristics, including high hardness, generally good elasticity, wear resistance, corrosion resistance, high-temperature resistance, etc. These characteristics make rubber sheets widely applicable in multiple fields.

Applications

Due to its excellent properties, rubber sheets have a wide range of applications, including but not limited to:

Sealing materials: Used to process various sealing gaskets and seals.

Protective materials: Used for the protection of various corrosive media, such as in the chemical, food manufacturing, and pharmaceutical industries, for the manufacture of containers for storing and transporting various corrosive liquids, gases, and solid materials.

Electrical insulation materials: Used for insulation in various electrical equipment in the power, electronics, and communications industries.

Sound insulation materials: Used for sound insulation in construction, decoration, and road traffic, such as floors, walls, ceilings, soundproof doors, soundproof windows, and elevated road sound barriers.

Shock absorption materials: Used for earthquake shock absorption and noise reduction in buildings.

Daily necessities: Used in the manufacture of toys, floor mats, etc.

Other industrial uses: Used in the plastics processing, casting, shoemaking, and clothing industries.

Production process

The production process of rubber sheets includes steps such as rubber mixing, rubber molding, rubber vulcanization, surface treatment, inspection and quality control, packaging and storage. These steps together ensure the quality and performance of the rubber sheet.

Rubber mixing: Rubber raw materials are crushed, sieved, and weighed, and mixed with various auxiliary agents such as vulcanizing agents, accelerators, and antioxidants through mixing machinery (such as rubber mills). The purpose of mixing is to ensure that the rubber and various auxiliary agents are fully and evenly dispersed, increasing the processability and physical and mechanical properties of the rubber.

Rubber molding: The mixed rubber is fed into equipment such as rubber calenders and rubber extruders for the molding of rubber sheets. These devices usually use heating and pressurization to allow the rubber to flow and fill in the mold, and maintain the required shape and size during subsequent cooling and vulcanization.

Rubber vulcanization: The molded rubber sheets need to undergo a vulcanization process to cause cross-linking reactions in the rubber material, improving the mechanical strength and wear resistance of the rubber. Vulcanization is usually carried out using high temperatures (approximately 150-180℃) and vulcanizing agents (such as sodium sulfide), and the time and temperature need to be determined according to the type and thickness of the rubber material.

Surface treatment: The vulcanized rubber sheets are processed to remove surface roughness, clean, and trim to improve the appearance quality and surface flatness of the rubber sheets.

Inspection and quality control: The finished rubber sheets are inspected, such as checking the dimensions, hardness, tensile strength, wear resistance, and other physical and mechanical properties, and evaluating and determining the product quality according to relevant standards.

Packaging and storage: Qualified rubber sheets are packaged, such as using plastic film for sealing, to facilitate protection and storage.

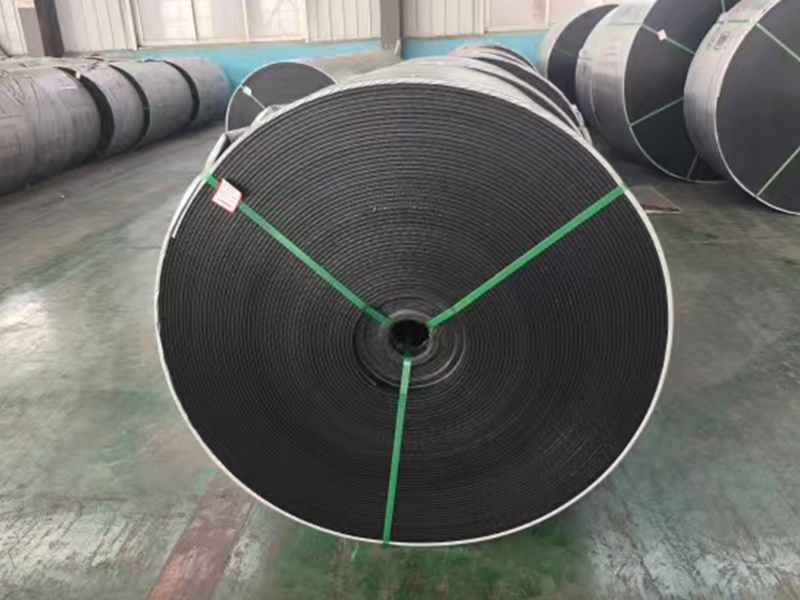

Packaging details

1. Waterproof nylon packaging, with a bottom steel pallet or wooden pallet.

2. Standard and appropriate export packaging.

3. Customized packaging is available according to customer requirements.

Shipping scenarios

Frequently asked questions

1. Can I customize rubber pads/sheets/blocks to meet my business needs?

►Yes, we are A professional manufacturer specializing in the customized production of conveyor belts and rubber pads/sheets/blocks. , We focus on customized conveyor belts and conveyor rollers, idler solutions. We work closely with our customers to customize products such as belt width, thickness, material composition, and various qualities according to the customer's specific operational requirements. This ensures that our conveyor belts perform ideally in different industrial environments.

2. What payment methods do you accept?

►We offer flexible payment methods to meet customer needs. Commonly used payment methods include Telegraphic Transfer (T/T) and Letter of Credit (L/C) ,especially suitable for large orders. We can also agree on other payment methods based on mutual agreement.

3. What after-sales service do you provide? And how do you guarantee your quality?

►We provide comprehensive after-sales service support, including 24/7 technical support, installation assistance, and maintenance suggestions 。We also provide regular follow-up services to ensure smooth product operation and long-term customer satisfaction! We have an in-house testing laboratory and adhere to the principle that products must pass inspection before leaving the factory! For many years, we have been one of the suppliers to internationally renowned companies, and our customers are located in various countries and regions, including mining, stone crushing, sand washing, ports, power plants, metallurgy, chemical industry, coal, steel plants, cement plants, construction, etc. Our excellent quality is widely praised.

4. How do I place an order? What is the delivery time?

►You can Contact us via WeChat, WhatsApp, phone, email, and website to place an order. For regular models, 5-7 days delivery ,the delivery time for other customized products depends on the product type and customization requirements.

5. Can I get samples for inspection and testing?

►Yes, samples can be sent for testing before bulk orders. Samples are created according to customer requirements, allowing customers to evaluate the performance of belts and rollers.

6. Can I print my LOGO on the rubber pads/sheets/blocks?

►Yes, we are a customized manufacturer, supporting processing, OEM, please inform us of your logo or design before mass production.

Why choose us?

1. Engineering design and consulting

Our conveyor belts are ideal for handling various heavy and abrasive materials in bulk material handling, successfully meeting the needs of various industries, including stone crushing and screening, sand washing, fertilizers, grain transportation, steel plants, power plants, cement plants, metallurgy, coal, ports, construction, etc. As a one-stop conveyor engineering manufacturer, we also provide excellent solutions for material handling problems and after-sales service for various applications.

2. Excellent customer service

We specialize in the production of heavy-duty (nylon, EP polyester, EE, NN) multi-ply fabric core rubber conveyor belts, steel cord conveyor belts, corrugated edge conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, and circular conveyor belts. As a leading Chinese conveyor belt manufacturer, supplier, and exporter, we are committed to providing customers with high-quality conveyor belts and professional services.

3. Customization

We support OEM and meet all your needs, regardless of size. Even if you only have an idea, we will help you realize it.

We have a strong R&D team that can develop and produce products according to customer-provided drawings or samples.

4. Cost-effectiveness

Same quality, lower price; same price, better quality. Fast production cycle, short lead time, high efficiency, durability, and reliable quality. We are committed to the mid-to-high-end market, and our products meet international standards.

Our Advantages

Excellent production equipment

The company has introduced multiple conveyor belt production lines and excellent production equipment.

Advanced technical strength

More than 500 engineering cases, advanced design and production processes, reliable product quality, and consistent customer praise.

Professional technical team

We have a professional scientific research team with industry experts and technicians with many years of experience.

Perfect after-sales service

A professional after-sales team is online 7*24 hours to provide you with star-rated intimate service, more peace of mind.

Production Capacity

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have pre-shipment inspection procedures?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

What are the payment terms?

Wire transfer or Letter of Credit, Western Union, Alipay, etc.

Can I have my own customized product?

Yes. OEM and ODM services are available, including design, logo, and packaging.

Rubber pad/rubber sheet/rubber block

Let our industry experts tailor a solution for you,Contact us!

Inquiry Now

Filling in your phone number and email information will help us contact you in time and quickly resolve the issues you raise.