Corrugated sidewall conveyor belt

Let our industry experts tailor a solution for you,Contact us!

- Product Description

-

Details

Usage

Due to site limitations or the need to lift materials at a large inclination angle, in order to prevent the scattering of conveyed materials, the sidewall conveyor belt must be able to withstand very high stresses and repeated bending that occur during high-volume, steep-angle conveying. High-quality, very low elongation polyester fabrics are used to provide higher stiffness values. This product is suitable for conveying materials under large inclination angles (0°-90°).

Features

• Conveying materials can achieve a large inclination angle up to 90°

• Large conveying capacity, materials will not scatter. Conveying can transition from horizontal to inclined, and from inclined to horizontal angles.

Standards

Type Tensile Strength N/mm Category Number of Carcass Layers Cover Rubber Thickness (mm) Weight (kg/m 2) Minimum Roller Diameter mm XE 200 Ordinary 2 2x2 9.8 200 XOE 315 Ordinary

Heat Resistant

Flame Retardant

2+1 4x2 11.3 315 500 3+1 4x2 13.2 400 630 4+1 4x2 14.9 500 800 5+1 4x2 17.8 630 1000 6+1 5x3 22.0 800 XUE 315 Ordinary 2+1 4x3 12.7 315 500 3+1 4x3 14.5 400 630 4+1 4x3 16.3 500 XDE 315 Ordinary 2+2 4x3 13.7 315 500 3+2 4x3 15.5 400 630 4+2 4x3 17.3 500 Corrugated Sidewall

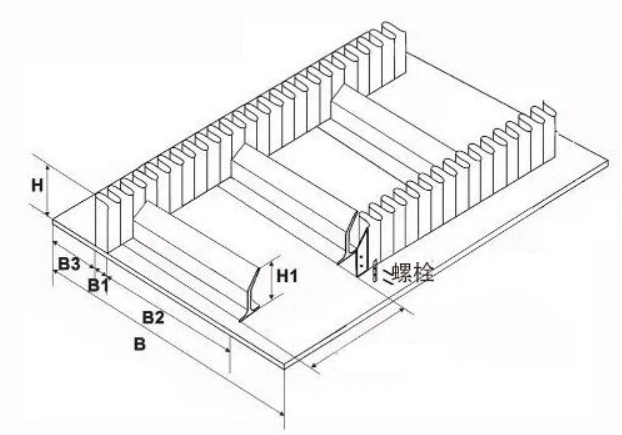

The sidewall is made of high-quality rubber.

There are also two types: pure rubber (BG) and rubber with fabric reinforcement layer (BGT)

Conveying Applications Height Sidewall Width Bottom Width Weight Minimum Roller Diameter mm mm mm mm mm N 80 44 50 1.6 200 100 44 50 1.8 250 S 120 66 75 3.1 320 160 66 75 4.1 400 200 66 75 5.1 500 240 66 75 6.1 550 ES 300 88 100 12.0 700 400 88 100 16.0 900 Note: N-Light Load; S-Medium Load; ES-Heavy Load.

Bulkhead

The bulkhead is made of high-quality rubber and has a high elastic support function.

There are also two types: pure rubber, rubber with fabric reinforcement layer

T

Type T75 T110 Height (mm) 75 110 Weight (Kg/m) 1.65 2.20 Minimum Roller Diameter (mm) 200 300 TC

Type TC110 TC140 TC180 TC220 TC260 Height (mm) 110 140 180 220 260 Weight (Kg/m) 2.6 5.5 7.0 8.0 10.2 Minimum Roller Diameter (mm) 350 370 450 500 600 TCS

Type TCS280 TCS360 Height (mm) 280 360 Weight (Kg/m) 18.5 22.0 Minimum Roller Diameter (mm) 700 700 Cover Rubber Quality/Grade Standard Performance Parameters

China GB/T7984-2013 GB/T 32457-2015 Conveyor Belt Cover Layer Performance Type Tensile Strength (ISO37)

MpaElongation at Break (ISO37)

%Abrasion Resistance (ISO4649)

mm 3H 24 450 120 D 18 400 100 L 15 350 200 German Standard DIN-22102 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Abrasion Loss ≥mm 3 Inter-Ply Adhesion Strength (N/mm) Adhesion Strength Between Cover and Carcass (/mm) Cover Thickness 0.8~1.5mm Cover Thickness >1.5mm W 18 400 90 ≥5 3.5 4.5 X 25 450 120 Y 20 400 150 Z 15 350 250 British Standard BS 490 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Abrasion Loss ≥mm 3 Inter-Ply Adhesion Strength (N/mm) Adhesion Strength Between Cover and Carcass (/mm) Cover Thickness 0.8~1.5mm Cover Thickness >1.5mm M 24 450 - ≥5.25 3.15 4.5 N 17 400 - Australian Standard AS 1332-2000 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Abrasion Loss ≥mm 3 Inter-Ply Adhesion Strength (N/mm) Adhesion Strength Between Cover and Carcass (/mm) Cover Thickness 0.8~1.5mm Cover Thickness >1.5mm A 17 400 70 6 4 4.8 E 14 300 - F 14 300 - M 24 450 125 N 17 400 200 S 14 300 250 S* 12 300 250 South African SANS 1173:2005 Grade Tensile Strength ≥Ma Elongation at Break ≥M% Abrasion Loss ≥mm 3 Inter-Ply Adhesion Strength (N/mm) Adhesion Strength Between Cover and Carcass (N/mm) A 18 400 90 ≥7 ≥5 X 25 450 120 M 24 450 150 N 20 400 250 Specifications and Technical Parameters of Corrugated Sidewall Multi-Ply Fabric Core Conveyor Belt

Fabric Type Fabric Structure Fabric Model Rubber Belt Thickness (mm/p) Strength Series (N/mm) Cover Rubber Thickness Width Range (mm) Warp Weft 2-ply 3-ply 4-ply 5-ply 6-ply Top Cover Layer Bottom Cover Layer Nylon

EP Polyester

NN

EE

Polyamide Polyamide Nylon/EP Polyester/NN/EE-100 1.00 200 300 400 500 600 0-12 0-10 300-2500 Nylon/EP Polyester/NN/EE-125 1.05 250 375 500 625 750 Nylon/EP Polyester/NN/EE-150 1.10 300 450 600 750 900 Nylon/EP Polyester/NN/EE-200 1.20 400 600 800 1000 1200 Nylon/EP Polyester/NN/EE-250 1.40 500 750 1000 1250 1500 Nylon/EP Polyester/NN/EE-300 1.60 600 900 1200 1500 1800 Bond strength and elongation performance meet the following table

Bond strength, elongation performance Core Material Bond Strength Elongation Performance Between fabric layers N/mm Between cover layer and fabric layer N/mm Full thickness longitudinal breaking elongation Full thickness longitudinal reference force elongation Cover layer thickness ≤1.5mm Cover layer thickness ≥1.5mm Polyester Canvas ≥5 ≥4.5 ≥5 ≥10% ≤4%6 The covering performance of the tape meets the following table

China GB/T7984-2013 GB/T 32457-2015 Tape cover layer performance Tape cover layer performance Cover Layer Grade Tensile Strength Elongation at Break Abrasion Loss Change rate of tensile strength and elongation at break after aging Mpa Kgf/cm2 % mm 3 % H ≥24 ≥240 ≥450 ≤120 -25~ +25 D ≥18 180 ≥400 ≤100 -25~ +25 L ≥15 150 ≥350 ≤200 -25~ +25 Packaging Details

1. Waterproof nylon packaging, wooden box, bottom steel pallet or wooden pallet.

2. Standard and appropriate export packaging.

3. Customized packaging can be provided according to customer requirements.

Shipping Scenarios

Frequently Asked Questions

1. Can I customize conveyor belts to meet my business needs?

►Yes, we are Specialized professional custom conveyor belt manufacturer , Focus on customized conveyor belt solutions. We work closely with our customers to customize the belt width, thickness, material composition, and various quality products according to the customer's specific operational requirements. This ensures that our conveyor belts perform ideally in different industrial environments.

2. What payment methods do you accept?

►We offer flexible payment methods to meet customer needs. Common payment methods include Telegraphic Transfer (T/T) and Letter of Credit (L/C) ,especially suitable for large orders. We can also negotiate other payment methods according to the agreement between both parties.

3. What after-sales service do you provide? And how do you guarantee your quality?

►We provide comprehensive after-sales service support, including 24/7 technical support, installation assistance and maintenance advice 。We also provide regular follow-up services to ensure smooth product operation and long-term satisfaction! We have an in-house testing laboratory and adhere to the principle that only qualified products can be shipped! For many years, we have been one of the suppliers to internationally renowned companies, and our customers are located in various countries and regions, including mining, stone crushing, sand washing, ports, power plants, metallurgy, chemical industry, coal, steel plants, cement plants, construction, etc. The excellent quality is widely praised.

4. How do I place an order? What is the delivery time?

►You can WeChat, WhatsApp, phone, email and website Contact us to place an order. Regular models 5-7 days delivery ,the delivery time for other customized products depends on the product type and customization requirements.

5. Can I get a sample for inspection and testing?

►Yes, samples can be sent for testing before bulk orders. Samples are created according to customer requirements, allowing customers to evaluate the performance of the belt and rollers.

6. Can I print my LOGO on the conveyor belt products?

►Yes, we are a custom manufacturer, support processing, support OEM, please inform us of your logo or design before mass production.

Why choose our conveyor belts?

1. Engineering Design and Consulting

Our conveyor belts are ideal for handling various heavy and abrasive materials in bulk material processing, successfully meeting the needs of various industries, including stone crushing and screening, sand washing, fertilizer, grain conveying, steel mills, power plants, cement plants, metallurgy, coal, ports and docks, construction, and more. As a one-stop conveyor engineering manufacturer, we also provide excellent solutions for conveying material problems and after-sales service for various applications.

2. Excellent Customer Service

We specialize in manufacturing heavy-duty (nylon, EP, EE, NN, polyester) multi-ply fabric core rubber conveyor belts, steel cord conveyor belts, corrugated sidewall conveyor belts, bucket elevator conveyor belts, chevron conveyor belts, ring conveyor belts, etc. As a leading Chinese conveyor belt manufacturer, supplier, and exporter, we are committed to providing customers with high-quality conveyor belts and professional services.

3. Customization

OEM support to meet all your needs, regardless of size. Even if you only have an idea, we will help you realize it.

We have a strong R&D team that can develop and manufacture products according to customer-provided drawings or samples.

4. Cost-effectiveness

Same quality, lower price; same price, better quality; fast production cycle; short lead time; efficient and durable; reliable quality. We are committed to the mid-to-high-end market, and our products meet international standards.

Our Advantages

Excellent production equipment

The company has introduced multiple conveyor belt production lines and excellent production equipment.

Advanced technical strength

More than 500 engineering cases, advanced design and production processes, reliable product quality, and consistent customer praise.

Professional technical team

We have a professional scientific research team with industry experts and technicians with many years of experience.

Perfect after-sales service

A professional after-sales team is online 7*24 hours to provide you with star-rated intimate service, more peace of mind.

Production Capacity

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have pre-shipment inspection procedures?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

What are the payment terms?

Wire transfer or Letter of Credit, Western Union, Alipay, etc.

Can I have my own customized product?

Yes. OEM and ODM services are available, including design, logo, and packaging.

Corrugated sidewall conveyor belt

Let our industry experts tailor a solution for you,Contact us!

Inquiry Now

Filling in your phone number and email information will help us contact you in time and quickly resolve the issues you raise.