Company Strength

Years of physical factory, strong strength

Non-standard Customization

Product supports processing and customization

On-time Delivery

Specialized technical team, on-time delivery

Intimate Service

One-to-one after-sales service

Shuanglong Rubber · Recommended Products

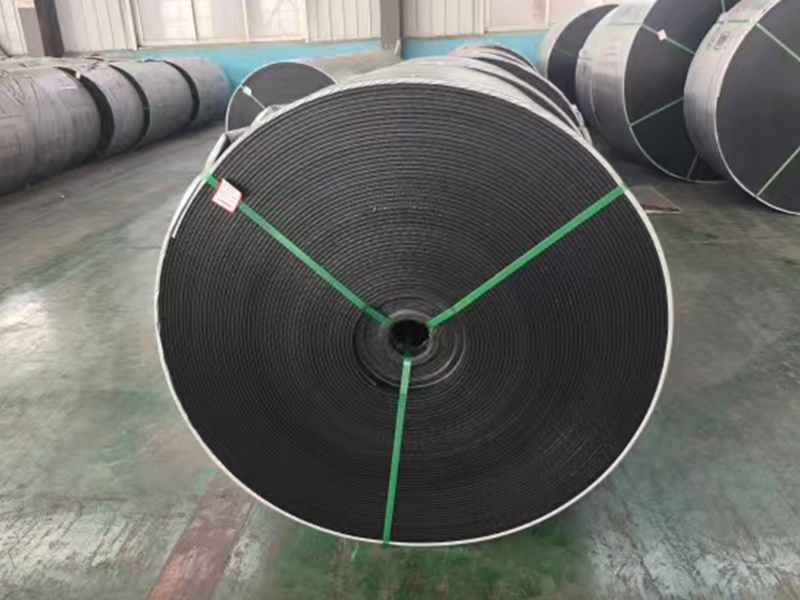

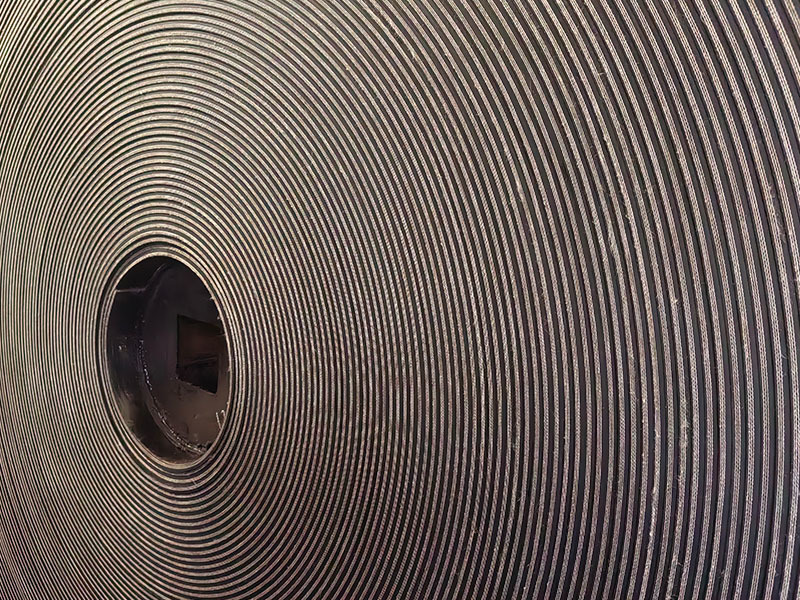

Nylon and rubber conveyor belts are especially suitable for mining, stone crushing and screening, sand washing, ports and docks, power, metallurgy, chemical industry, coal, steel plants, cement plants, construction and other industries. They are suitable for most medium/long distances, high loads, and high-speed material conveying conditions.

High wear-resistant conveyor belt

High wear-resistant and energy-saving multi-layer fabric core (nylon/EP polyester/NN/EE) rubber conveyor belts are especially suitable for mining stone crushing and screening, sand washing, ports and docks, chemical fertilizers, power, metallurgy, chemical industry, steel plants, cement plants, coal, docks, construction and other industries. They feature energy saving and wear resistance, and are suitable for most short/medium/long distances, high loads, and high-speed material conveying conditions.

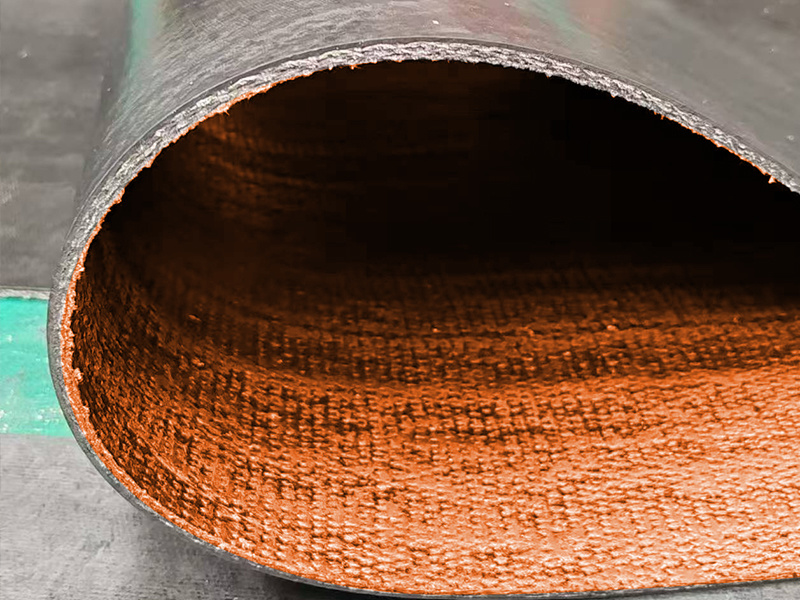

Heat-resistant (EP) polyester conveyor belt

Heat-resistant conveyor belts are mainly used for conveying high-temperature materials, such as sintered ore, hot coke, cement clinker, and hot castings. According to the main manifestations of damage and loss of conveying capacity of heat-resistant belts and different heat-resistant levels, ethylene propylene rubber or styrene-butadiene rubber is used as the cover rubber; high-strength and high-permeability polyester canvas or cotton canvas is used as the strong layer. Heat-resistant glass cloth can be laid between the cover rubber and the carcass layer to improve the service life of the heat-resistant belt. According to customer requirements, it can be made into a ring belt.

Underground PVG solid-core flame-retardant conveyor belt

Overall core flame-retardant conveyor belt (PVC-PVG) is mainly used in coal mine underground. Features of this belt: the belt body does not delaminate, small elongation, impact resistance, tear resistance. According to different structures, it can be divided into PVC type (plastic surface) and PVG type (rubber surface added on the basis of PVC) whole-core flame-retardant belts, which comply with MT914-2002 standard.

Flower patterned herringbone conveyor belt

The patterned conveyor belt has a wide range of uses. With a material conveying angle of 0°--45°, it prevents material slippage and improves conveying efficiency. It can be used to convey cement clinker, lime, sand and gravel, domestic or industrial waste, coal, and various bagged items. It is widely used in the coal, mining, power, chemical, steel, and grain industries.

Wire rope conveyor belts have proven to be a very reliable and cost-effective method for conveying bulk materials in long-distance conveyors. We offer laterally reinforced belts, belts with embedded sensor coils, and standard wire rope conveyor belts.

Upper convex inverted V-shaped pattern conveyor belt

The patterned conveyor belt has a wide range of uses. With a material conveying angle of 0°--45°, it prevents material slippage and improves conveying efficiency. It can be used to convey cement clinker, lime, sand and gravel, domestic or industrial waste, coal, and various bagged items. It is widely used in the coal, mining, power, chemical, steel, and grain industries.

Backless/backless conveyor belt

Backless type is suitable for lightweight materials. A backless conveyor belt runs on steel, wood, or other low-friction surfaces (sliding bed), and is suitable for conveying with low friction. Compared with standard conveyor belts, the difficult wear between the conveyor belt and the frame is reduced, thus greatly reducing the wear of the conveyor belt and improving efficiency.

The edge conveyor belt covering is made of nitrile rubber with excellent oil resistance, featuring oil resistance, heat resistance, and corrosion resistance. Suitable for conveying oily materials or in environments where it contacts various working oils. Both sides are neat, running stably without deviation, accurately positioning materials. Made of high-strength wear-resistant material, it is resistant to pulling and tearing, and has strong load-bearing capacity. Adaptable to high-temperature and chemical complex environments. The surface is anti-slip and anti-static, safe and reliable, and easy to maintain and replace, effectively improving conveying efficiency. Reinforced materials can be selected according to different customer needs.

Ultra-wide conveyor belts are mainly used for large-volume material transportation in industrial sectors such as mining, steel, and cement; parcel and goods sorting and transportation in logistics; bulk cargo loading and unloading in ports; material transportation in construction; and grain transportation and processing in agriculture.

Product Classification · Understand Your Needs

Mainly engaged in the research, development, production and sales of conveyor machinery and accessories

Through the integration of advanced production equipment and scientific modern management, the quality of products is effectively guaranteed, creating products that meet customer needs

22 years of experience

Cooperative Customers

Existing Employees

Craftsmanship Quality

Excellent production equipment

The company has introduced multiple conveyor belt production lines and excellent production equipment.

Advanced technical strength

More than 500 engineering cases, advanced design and production processes, reliable product quality, and consistent customer praise.

Professional technical team

We have a professional scientific research team with industry experts and technicians with many years of experience.

Perfect after-sales service

A professional after-sales team is online 7*24 hours to provide you with star-rated intimate service, more peace of mind.

ABOUT US

More than 30 years focusing on conveyor belt solutions

One-stop service to save you time and worry

Technical personnel

Factory area

Hebei Shuanglong Rubber Co., Ltd. was established in 1993 and has undergone more than 30 years of development. It is now located in the nationally renowned rubber hometown of Jizhong Plain - Duikan Zhuang Industrial Park, Lixian County, Baoding City. The company covers an area of more than 50,000 square meters and has more than 300 employees. It also has a strong technical team. The company currently has 20 engineering and technical personnel, including 2 senior engineers (formerly worked in the R&D department of Qingdao Liu), 8 engineers, and 10 other engineering and technical personnel.

Original manufacturer · Support customization

GLOBAL NETWORK

Providing global services to our customers

Serving customers from 40 countries300customers

A variety of marketing models have created a perfect sales and service system, with products exported and serving more than 40 countries and regions, including Russia, Mexico, Peru, and Spain. We are committed to developing enterprises and products with excellent service.

Product Solutions

NEWS & BLOG

Shuanglong Rubber · News

Do you have any questions?

For a quick reply, please fill out the form and our team will get back to you shortly.